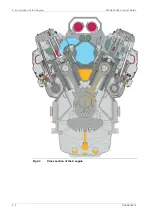

exhaust side. The wastegate arrangement permits a part of the exhaust gas to bypass the

turbine in the turbocharger at high engine load.

Variable speed engines are additionally equipped with a by-pass valve to increase the flow

through the turbocharger at low engine speed and low engine load. Part of the charge air is

conducted directly into the exhaust gas manifold (without passing through the engine), which

increases the speed of the turbocharger. The net effect is increased charge air pressure at

low engine speed and low engine load, despite the apparent waste of air.

All engines are provided with devices for water cleaning of the turbine and the compressor.

The cleaning is performed during operation of the engine.

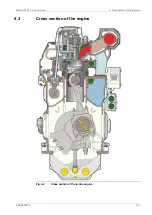

The engines have a transversely installed turbocharger. The turbocharger can be located at

either end of the engine and the exhaust gas outlet can be vertical, or inclined 45 degrees in

the longitudinal direction of the engine.

A two-stage charge air cooler is standard. Heat is absorbed with high temperature (HT) cooling

water in the first stage, while low temperature (LT) cooling water is used for the final air cooling

in the second stage. The engine has two separate cooling water circuits. The flow of LT cooling

water through the charge air cooler is controlled to maintain a constant charge air temperature.

4.2.15

Automation system

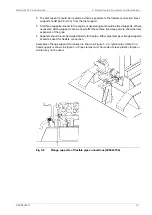

This engine is equipped with a modular embedded automation system, Wärtsilä Unified

Controls - UNIC.

The system version UNIC C2 has a hardwired interface for control functions and a bus

communication interface for alarm and monitoring.

An engine safety module and a local control panel mounted on the engine. The engine safety

module handles fundamental safety, for example overspeed and low lubricating oil pressure

shutdown. The safety module also performs fault detection on critical signals and alerts the

alarm system about detected failures. The local control panel has push buttons for local

start/stop and shutdown reset, as well as a display showing the most important operating

parameters. Speed control is included in the automation system on the engine.

All necessary engine control functions are handled by the equipment on the engine, bus

communication to external systems and a more comprehensive local display unit.

Conventional heavy duty cables are used on the engine and the number of connectors are

minimized. Power supply, bus communication and safety-critical functions are doubled on

the engine. All cables to/from external systems are connected to terminals in the main cabinet

on the engine.

4.2.16

Variable Inlet valve Closure, optional

Variable Inlet valve Closure (VIC), which is available as an option, offers flexibility to apply early

inlet valve closure at high load for lowest NOx levels, while good part-load performance is

ensured by adjusting the advance to zero at low load. The inlet valve closure can be adjusted

up to 30° crank angle.

4-4

DAAB605814

Wärtsilä 46F Product Guide

4. Description of the Engine

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...