15.

Foundation

Engines can be either rigidly mounted on chocks, or resiliently mounted on steel spring

elements. If resilient mounting is considered, Wärtsilä must be informed about existing

excitations such as propeller blade passing frequency. Dynamic forces caused by the engine

are listed in the chapter Vibration and noise.

15.1

Steel structure design

The system oil tank should not extend under the reduction gear or generator, if the oil tank is

located beneath the engine foundation. Neither should the tank extend under the support

bearing, in case there is a PTO arrangement in the free end. The oil tank must also be

symmetrically located in transverse direction under the engine.

The foundation and the double bottom should be as stiff as possible in all directions to absorb

the dynamic forces caused by the engine, reduction gear and thrust bearing.

The foundation should be dimensioned and designed so that harmful deformations are avoided.

The foundation of the driven equipment should be integrated with the engine foundation.

15.2

Engine mounting

The mounting arrangement is similar for diesel electric installations and conventional propulsion.

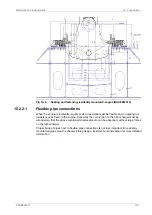

15.2.1

Rigid mounting

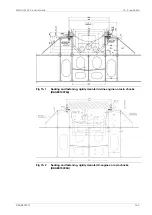

Engines can be rigidly mounted to the foundation either on steel chocks or resin chocks.

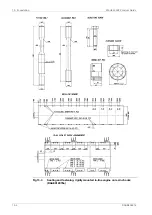

The holding down bolts are through-bolts with a lock nut at the lower end and a hydraulically

tightened nut at the upper end. The tool included in the standard set of engine tools is used

for hydraulic tightening of the holding down bolts. Bolts number two and three from the flywheel

end on each side of the engine are to be Ø46 H7/n6 fitted bolts. The rest of the holding down

bolts are clearance bolts.

A distance sleeve should be used together with the fitted bolts. The distance sleeve must be

mounted between the seating top plate and the lower nut in order to provide a sufficient

guiding length for the fitted bolt in the seating top plate. The guiding length in the seating top

plate should be at least equal to the bolt diameter.

The design of the holding down bolts appear from the foundation drawing. It is recommended

that the bolts are made from a high-strength steel, e.g. 42CrMo4 or similar. A high strength

material makes it possible to use a higher bolt tension, which results in a larger bolt elongation

(strain). A large bolt elongation improves the safety against loosening of the nuts.

To avoid a gradual reduction of tightening tension due to unevenness in threads, the threads

should be machined to a finer tolerance than normal threads. The bolt thread must fulfil

tolerance 6g and the nut thread must fulfil tolerance 6H. In order to avoid bending stress in

the bolts and to ensure proper fastening, the contact face of the nut underneath the seating

top plate should be counterbored.

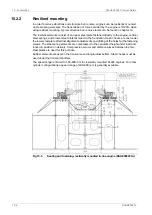

Lateral supports must be installed for all engines. One pair of supports should be located at

the free end and one pair (at least) near the middle of the engine. The lateral supports are to

be welded to the seating top plate before fitting the chocks. The wedges in the supports are

to be installed without clearance, when the engine has reached normal operating temperature.

The wedges are then to be secured in position with welds. An acceptable contact surface

must be obtained on the wedges of the supports.

DAAB605814

15-1

15. Foundation

Wärtsilä 46F Product Guide

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...