500 cSt

Viscosity for dimensioning of electric motor

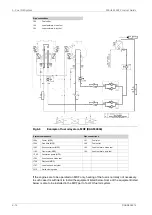

Heater, booster unit (1E02)

The heater must be able to maintain a fuel viscosity of 14 cSt at maximum fuel consumption,

with fuel of the specified grade and a given day tank temperature (required viscosity at injection

pumps stated in Technical data). When operating on high viscosity fuels, the fuel temperature

at the engine inlet may not exceed 135°C however.

The power of the heater is to be controlled by a viscosimeter. The set-point of the viscosimeter

shall be somewhat lower than the required viscosity at the injection pumps to compensate

for heat losses in the pipes. A thermostat should be fitted as a backup to the viscosity control.

To avoid cracking of the fuel the surface temperature in the heater must not be too high. The

heat transfer rate in relation to the surface area must not exceed 1.5 W/cm

2

.

The required heater capacity can be estimated with the following formula:

where:

heater capacity (kW)

P =

total fuel consumption at full 15% margin [l/h]

Q =

temperature rise in heater [°C]

Δ

T =

Viscosimeter, booster unit (1I02)

The heater is to be controlled by a viscosimeter. The viscosimeter should be of a design that

can withstand the pressure peaks caused by the injection pumps of the diesel engine.

Design data:

0...50 cSt

Operating range

180°C

Design temperature

4 MPa (40 bar)

Design pressure

6.3.6.5

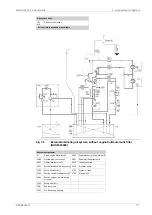

Pump and filter unit (1N03)

When more than two engines are connected to the same feeder/booster unit, a circulation

pump (1P12) must be installed before each engine. The circulation pump (1P12) and the safety

filter (1F03) can be combined in a pump and filter unit (1N03). A safety filter is always required.

There must be a by-pass line over the pump to permit circulation of fuel through the engine

also in case the pump is stopped. The diameter of the pipe between the filter and the engine

should be the same size as between the feeder/booster unit and the pump and filter unit.

Circulation pump (1P12)

The purpose of the circulation pump is to ensure equal circulation through all engines and to

maitain the required pressure at the injection pumps.

Design data:

LFO:2cSt HFO:20cSt

Capacity

DAAB605814

6-27

6. Fuel Oil System

Wärtsilä 46F Product Guide

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...