7.3.3

Suction strainers (2F01, 2F04, 2F06)

It is recommended to install a suction strainer before each pump to protect the pump from

damage. The suction strainer and the suction pipe must be amply dimensioned to minimize

pressure losses. The suction strainer should always be provided with alarm for high differential

pressure.

Design data:

0.5...1.0 mm

Fineness

7.3.4

Lubricating oil pump ( 2P04)

The stand-by lubricating oil pump is normally of screw type and should be provided with an

safety valve.

Design data:

see Technical data

Capacity

1.0 MPa (10 bar)

Design pressure

800 kPa (8 bar)

Max. pressure (safety valve)

100°C

Design temperature

500 cSt

Viscosity for dimensioning the electric

motor

Example of required power, oil temperature 40°C. The actual power requirement is determined

by the type of pump and the flow resistance in the external system.

16V46F

14V46F

12V46F

9L46F

8L46F

7L46F

6L46F

78

78

65

60

50

50

45

Pump [kW]

87

87

75

75

55

55

55

Electric motor [kW]

7.3.5

Pre-lubricating oil pump (2P02)

The pre-lubricating oil pump is a separately installed scew or gear pump, which is to be

equipped with a safety valve.

The installation of a pre-lubricating pump is mandatory. An electrically driven main pump or

standby pump (with full pressure) may not be used instead of a dedicated pre-lubricating

pump, as the maximum permitted pressure is 200 kPa (2 bar) to avoid leakage through the

labyrinth seal in the turbocharger (not a problem when the engine is running). A two speed

electric motor for a main or standby pump is not accepted.

The piping shall be arranged so that the pre-lubricating oil pump fills the main oil pump, when

the main pump is engine driven.

The pre-lubricating pump should always be running, when the engine is stopped.

Depending on the foreseen oil temperature after a long stop, the suction ability of the pump

and the geometric suction height must be specially considered with regards to high viscosity.

With cold oil the pressure at the pump will reach the relief pressure of the safety valve.

Design data:

see Technical data

Capacity

7-12

DAAB605814

Wärtsilä 46F Product Guide

7. Lubricating Oil System

Summary of Contents for 46F Series

Page 1: ...Wärtsilä 46F PRODUCT GUIDE ...

Page 4: ...This page intentionally left blank ...

Page 8: ...This page intentionally left blank ...

Page 18: ...This page intentionally left blank ...

Page 86: ...This page intentionally left blank ...

Page 104: ...This page intentionally left blank ...

Page 154: ...This page intentionally left blank ...

Page 162: ...This page intentionally left blank ...

Page 170: ...This page intentionally left blank ...

Page 176: ...This page intentionally left blank ...

Page 194: ...This page intentionally left blank ...

Page 200: ...This page intentionally left blank ...

Page 202: ...This page intentionally left blank ...

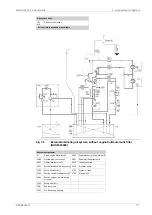

Page 207: ...Fig 21 7 List of symbols DAAF406507 7 DAAB605814 21 5 21 ANNEX Wärtsilä 46F Product Guide ...