113

5790 733 - 07

Vitocrossal 300 CA3 Series 2.5 to 6.0 Installation/Service

Service

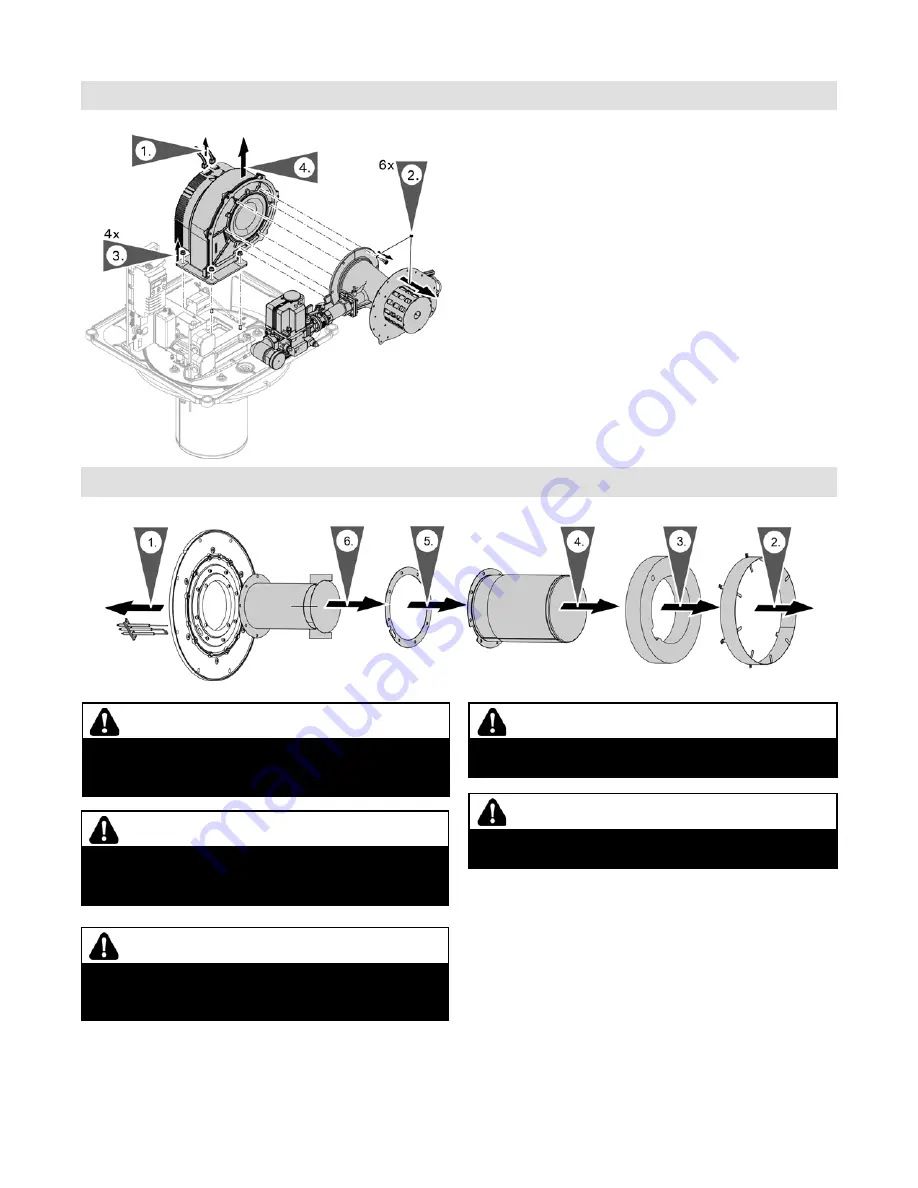

Checking and Cleaning the Burner Tube

1. Remove the electrodes (if required).

2. Undo 6 screws from the insulation ring.

Torque when installing: 13 lb.in (1.5 Nm.)

3. Remove the insulation ring.

4. Unscrew the burner gauze assembly.

You can now vacuum or replace the burner gauze

assembly. Torque when installing: 7.5 lb.ft (10 Nm.)

5. Replace all gaskets. Reassemble burner tube and burner

in reverse order. Torque: 7.5 lb.ft (10 Nm).

6. Remove the insulation ring.

WARNING

Gas leakage can lead to risk of explosion. Close gas

shut-off valve.

WARNING

Contact with hot surfaces can lead to burn injuries.

Undertake work on the burner only when the system is cold.

CAUTION

Scratches in the combustion chamber can lead to

corrosion. Do not allow any tools or other objects to

fall into the combustion chamber.

CAUTION

Contamination of the burner tube can lead to malfunctions.

When exchanging the burner tube, ensure that no fibres

from the heat insulation block stick to the burner tube.

CAUTION

Improperly executed exchange of the burner tube can lead

to contamination of the combustion chamber. Ensure that the

combustion chamber is maintained free of insulation

fi

bres.

Fan

1. Disconnect both connectors from the fan.

2. Remove 6 nuts on the Venturi pipe. Remove the

Venturi pipe with the fitted gas valve.

Torque when installing: 4.5 lb.ft (6 Nm).

3. Undo the hexagon nuts from the 4 studs.

4. Remove the fan, noting how the gasket is positioned.

5. Installation in reverse order.

Note:

Fit gasket in the correct position.

6. For further steps, see chapter “Further assembly”

on page 117.