DSGH Installation and Operation Guide

27

Installation

Location considerations

When you ordered the gauge, VEGA sized the source for optimal

performance. Notify VEGA before installing the gauge if its location

differs. Satisfactory operation depends on proper location.

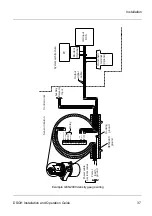

Vertical pipe with upward flow

Mount the measuring assembly on a vertical pipe with upward flow of the

process material. This position provides the best possible self-cleaning

action, with a minimum possibility of gas or heavy solids collecting in the

measuring section. You can mount the gauge on a horizontal pipe but a

vertical flow is preferable. Keep the velocity above five feet per second

to avoid build-up on the pipe walls and to keep the heavier solids in

suspension. This is particularly true in sludge applications.

Pump considerations

Mounting the density gauge near a pump can be good or bad depending

on the application. Check with VEGA application engineers for a

recommendation on your application.

No line hammering

The design of the density gauge requires operation in low-vibration

conditions. Install it in a location with no line hammering or excessive

vibration. Quickly changing flow conditions may cause line hammering. If

Note: Locate the source holder where process material cannot coat it.

This ensures the continuing proper operation of the source ON/

OFF mechanism (if applicable). Many regulatory bodies

(example: the U.S. NRC) require periodic testing of the ON/OFF

mechanism.

See the Radiation Safety for U.S. General and Specific

Licensees, Canadian and International Users Manual and the

Radiation Safety Manual Addendum of Reference Information

CD that came with the source holder and the appropriate

current regulations for details.

Summary of Contents for DSGH

Page 2: ......

Page 4: ...2 DSGH Installation and Operation Guide NOTES ...

Page 8: ...6 DSGH Installation and Operation Guide NOTES ...

Page 12: ...10 DSGH Installation and Operation Guide Preface NOTES ...

Page 32: ...30 DSGH Installation and Operation Guide Installation Mounting the DSGH gauge ...

Page 56: ...54 DSGH Installation and Operation Guide Calibration NOTES ...

Page 94: ...92 DSGH Installation and Operation Guide Diagnostics and repair NOTES ...

Page 98: ...96 DSGH Installation and Operation Guide NOTES ...

Page 99: ......