HF25D DC RESISTANCE WELDING SYSTEM

990-333

B-1

APPENDIX B

ELECTRICAL AND DATA CONNECTIONS

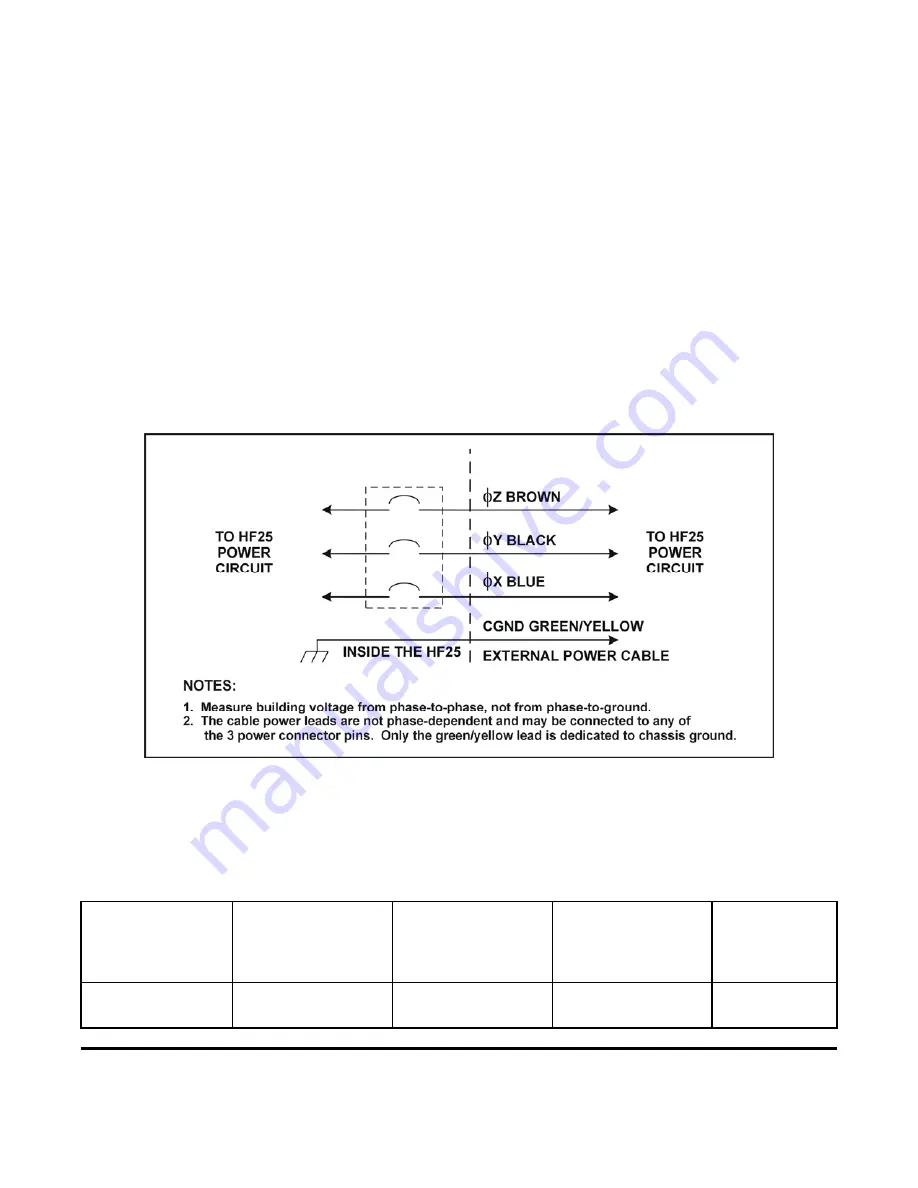

Electrical Connection

As described in

Chapter 2

, you need to supply a connector for the Control input power cable (refer to

diagram below for wiring information).

Connect the Control power cable to a 3-phase, 50/60Hz power source. The voltage range for each

model is set at the factory by a set of two jumper plugs. One jumper plug is installed on power

connector J23, located on the center chassis plate. The other jumper plug, P22, plugs into welding

transformer cable connector J22. The jumper plug set determines the power wiring configuration

between the power board and the welding transformer.

Input Power Wiring Diagram

CAUTIONS:

•

Be sure that the shop source power is appropriate for your Control model.

•

If the blue phase wire is

not

connected,

no

alarm will occur and the weld control will produce

more than 20% ripple in the weld output waveform.

Welding Transformer Specifications

Model

Max Peak Output

Current (A)

Max Peak Output

Voltage (V) at Max

Peak Output

Current

Duty Cycle at Max

Peak Output

Current

Max Load

Resistance

(m

Ω

) for Max

Output Current

HF25A10

(all voltages)

2,400 5.2 3%

2.1

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......