CHAPTER 4. OPERATING INSTRUCTIONS

HF25D DC RESISTANCE WELDING SYSTEM

990-333

4-3

Section II. Programming Weld Schedules

Introduction

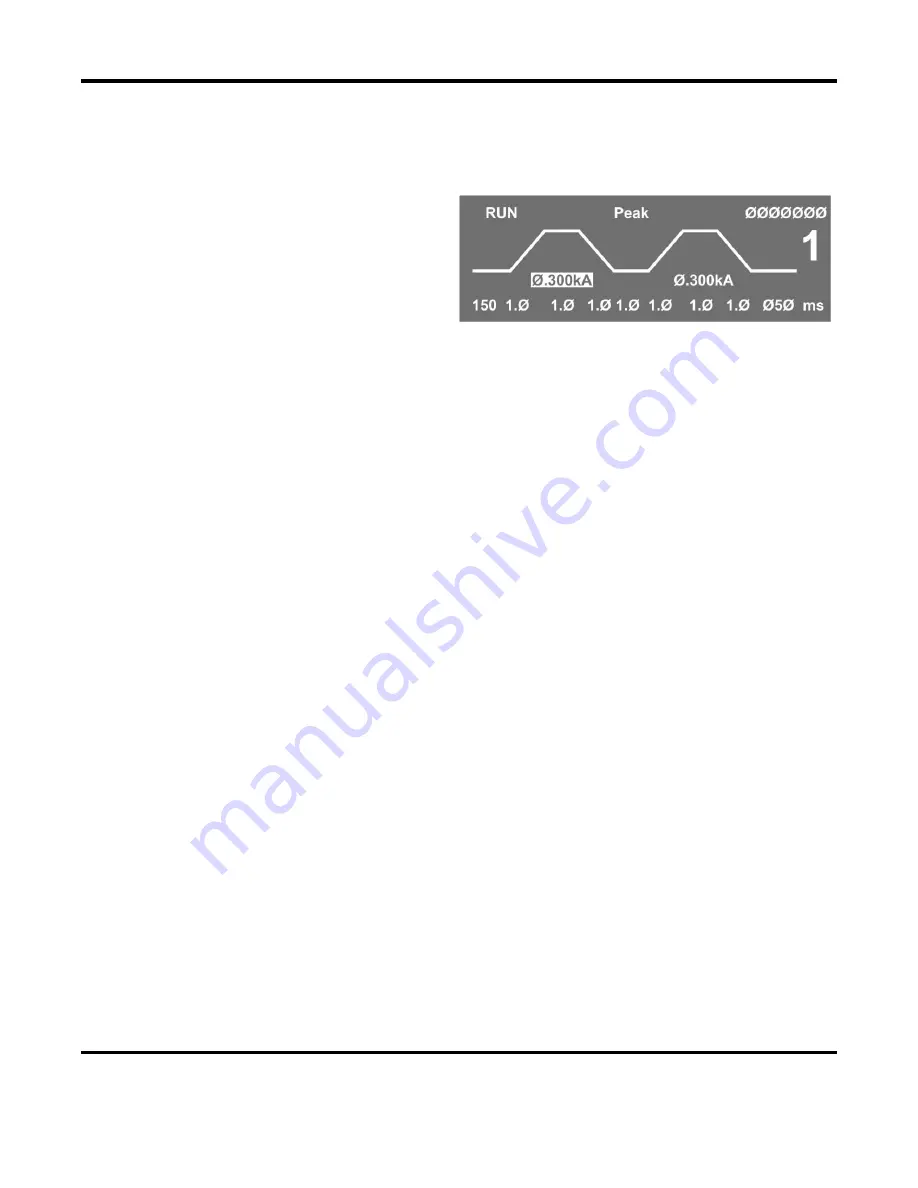

The Control comes with 99 factory-installed

weld schedules, numbered from

01

through

99

.

Each schedule looks like the display on the right.

See

Section III, Using HF25 Welding And

Monitoring Functions

for descriptions of the

features available in weld schedules.

The process of

Programming

a weld schedule consists of:

•

Select

a weld schedule.

•

Enter

new values in the selected schedule.

NOTE:

For reference and convenience, you might want to keep a written list of your programmed weld

schedule values using the two-digit weld schedule number.

Select A Weld Schedule

1.

To select weld schedules, first make sure that the

RUN

state is displayed on the LCD. If

not, press the

RUN

key on the front of the Control.

2.

Press the

SCHEDULE

key on the right of the Control.

3.

Use

either

of the methods below to select a schedule:

•

Use the

VW

(Up/Down) keys to scroll through the list.

OR

•

Use the numeric keypad to enter the two-digit number of the schedule you want.

Enter New Values

Some welding applications require no more than a simple weld schedule, programmed for Single-

Pulse, Upslope/Downslope, or Dual-Pulse operation. For other applications, you may want to use

the

Energy Limits Monitor

or

Active Part Conditioning

features of the Control. To

enter new

values

, follow the instructions for Single-Pulse, Upslope/Downslope, or Dual-Pulse weld schedules

on the following pages.

NOTE:

If drastically different energy values are entered for Pulse 1 and Pulse 2, the Control will

require a minimum of 0.5 ms Cool Time. If different feedback modes are programmed for a dual

pulse weld, the Control will require a minimum of 0.5 ms Cool Time. If a Cool Time is set lower

than 0.5 ms, but not zero, the Control will default to 0.5 ms Cool Time.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......