CHAPTER 3: USING PROGRAMMING FUNCTIONS

HF25 DC RESISTANCE WELDING SYSTEM

3-10

990-333

SETUP 1

1. Footswitch Weld Abort

From the

SETUP 1

screen, press the

1

key to toggle between

ON

and

OFF

. This function controls how

the Control interfaces with a foot switch, a force firing switch, or a programmable logic control (PLC).

Any of these switches could be the weld initiation switch in your system setup.

ON

means that the welding process is initiated by closure of the initiation switch and continues to its

conclusion while the initiation switch remains closed. If the initiation switch opens during the welding

process, the welding process will terminate. The

ON

state is preferred for human operated welding

stations since it allows you to abort the weld process by releasing the foot switch (or the foot pedal in the

case of a manually actuated weld head).

OFF

is preferred for computer or PLC controlled welding stations since a single start pulse can be used

to initiate the welding process. To select the

ON/OFF

states, press the

1

key. The

FOOTSWITCH WELD

ABORT

line will now reflect your selection.

2. Switch Debounce Time

The contacts of single pole mechanical firing switches “bounce” when they close. The switch de-

bounce time function allows you to specify that the initiation switch contacts must remain closed for 10,

20, or 30 milliseconds before the weld period can be initiated, thereby avoiding false starts caused by the

switch contact bouncing.

1.

From the

SETUP 1

screen, press the

2

key to go to the

SWITCH DE-BOUNCE

TIME

menu screen.

2.

Select the required debounce time by

pressing the

1

,

2

,

3

or

4

key.

NONE

represents a debounce time of 0 ms.

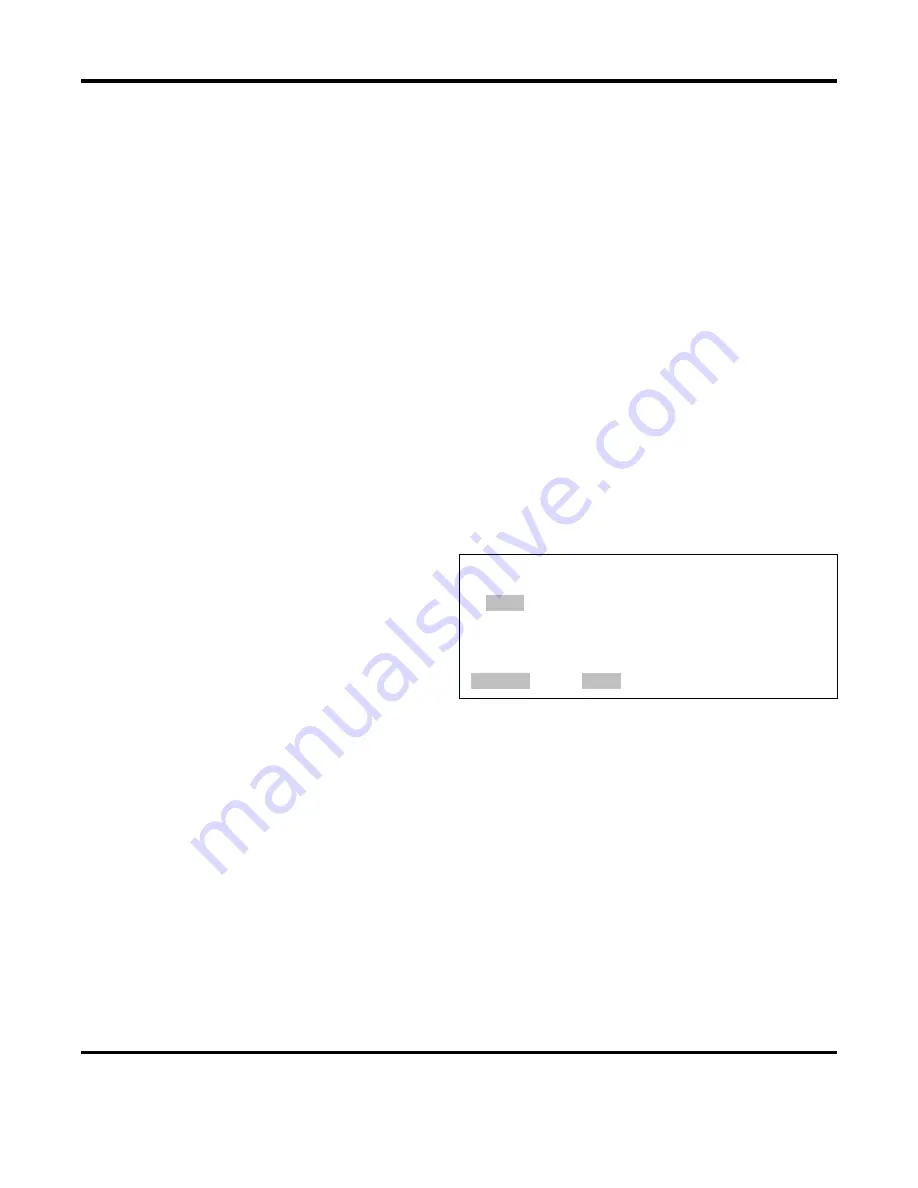

<SWITCH DEBOUNCE TIME>

1. NONE

2. 10 ms

3. 20 ms

4. 30 ms

NUMBER Select, MENU Previous menu

Use

NONE

for interfacing with the Unitek Peco Model 350C Electronic Weld Force Control.

3.

Press the

MENU

key to return to the

SETUP 1

screen. The

SWITCH DEBOUNCE TIME

line

will now reflect your switch debounce time selection.

Summary of Contents for HF25A

Page 9: ...HF25D DC RESISTANCE WELDING SYSTEM 990 333 ix ...

Page 10: ......

Page 20: ......

Page 84: ...CHAPTER 6 CALIBRATION HF25D DC RESISTANCE WELDING SYSTEM 990 333 6 4 Final Calibration Setup ...

Page 113: ......

Page 129: ......

Page 153: ......

Page 171: ......