7

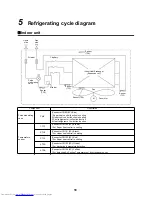

Refrigerant

The refrigerant used by this Air to Air Heat Exchanger with DX Coil Unit is the R410A.

Check the used refrigerant name and use tools and materials of the parts which match with it.

For the products which use R410A refrigerant, the refrigerant name is indicated at a position on the outdoor

unit where is easy to see. To prevent miss-charging, the route of the service port is changed from one of the

former R22.

For an Air to Air Heat Exchanger with DX Coil Unit which uses R410A, never use other refrigerant than

R410A. For an Air to Air Heat Exchanger with DX Coil Unit which uses other refrigerant (R22, etc.), never

use R410A.

If different types of refrigerant are mixed, abnormal high pressure generates in the refrigerating cycle and an

injury due to breakage may be caused.

When the Air to Air Heat Exchanger with DX Coil Unit has been installed or relocated, follow the instructions

in the Installation Manual and purge the air completely so that no gases other than the refrigerant will be

mixed in the refrigerating cycle. Failure to purge the air completely may cause the Air to Air Heat Exchanger

with DX Coil Unit to malfunction.

Do not charge refrigerant additionally. If charging refrigerant additionally when refrigerant gas leaks, the

refrigerant composition in the refrigerating cycle changes resulted in change of Air to Air Heat Exchanger with

DX Coil Unit characteristics or refrigerant over the specified standard amount is charged and an abnormal

high pressure is applied to the inside of the refrigerating cycle resulted in cause of breakage or injury.

Therefore if the refrigerant gas leaks, recover the refrigerant in the Air to Air Heat Exchanger with DX Coil

Unit, execute vacuuming, and then newly recharge the specified amount of liquid refrigerant.

In this time, never charge the refrigerant over the specified amount.

When recharging the refrigerant in the refrigerating cycle, do not mix the refrigerant or air other than R410A

into the specified refrigerant. If air or others is mixed with the refrigerant, abnormal high pressure generates

in the refrigerating cycle resulted in cause of injury due to breakage.

After installation or servicing work, check the refrigerant gas does not leak. If the refrigerant gas leaks in the

room, poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though

the refrigerant gas itself is innocuous.

Never recover the refrigerant into the outdoor unit. When the equipment is moved or repaired, be sure to

recover the refrigerant with recovering device.

The refrigerant cannot be recovered in the outdoor unit; otherwise a serious accident such as breakage or

injury is caused.

Assembly /

Wiring

After repair work, surely assemble the disassembled parts, and connect and lead the removed wires as

before.

Perform the work so that the electrical control cover does not catch the inner wires.

If incorrect assembly or incorrect wire connection was done, a disaster such as a leak or fire is caused at

user’s side.

Insulator check

After the work has finished, be sure to use an insulation tester set (500 V Megger) to check the resistance is

1 M

:

or more between the charge section and the non-charge metal section (Earth position).

If the resistance value is low, a disaster such as a leak or electric shock is caused at user’s side.

Ventilation

When the refrigerant gas leaks during work, execute ventilation.

If the refrigerant gas touches to a fire, poisonous gas generates. A case of leakage of the refrigerant and the

closed room full with gas is dangerous because a shortage of oxygen occurs. Be sure to execute ventilation.

Compulsion

When the refrigerant gas leaks, find up the leaked position and repair it surely.

If the leaked position cannot be found up and the repair work is interrupted, pump-down and tighten the

service valve, otherwise the refrigerant gas may leak into the room.

The poisonous gas generates when gas touches to fire such as fan heater, stove or cocking stove though

the refrigerant gas itself is innocuous.

When installing equipment which includes a large amount of charged refrigerant such as a multi air

conditioner in a sub-room, it is necessary that the density does not the limit even if the refrigerant leaks.

If the refrigerant leaks and exceeds the limit density, an accident of shortage of oxygen is caused.

Tighten the flare nut with a torque wrench in the specified manner.

Excessive tighten of the flare nut may cause a crack in the flare nut after a long period, which may result in

refrigerant leakage.

Nitrogen gas must be used for the airtight test.

The charge hose must be connected in such a way that it is not slack.

For the installation / moving / reinstallation work, follow to the Installation Manual.

If an incorrect installation is done, a trouble of the refrigerating cycle, water leak, electric shock or fire is

caused.

Summary of Contents for MD-VNK802HEXE

Page 120: ...118 11Owner s Manual Excerpt ...

Page 137: ...135 12Installation Manual Excerpt ...