BLZZRD Portable Refrigerated Sampler

Section 5 Extended Programming

5-10

Selecting a Stored Extended Program, continued…

53. Select NUMBER OF SAMPLES.

54. Enter 1.

55. Select NO.

56. Enter 500.

57. Select RAIN.

58. Select AND.

59. Select LEVEL.

60. Enter 0.15 for inches, then enter 30 minutes.

61. Select ABOVE SET POINT.

62. Select YES.

63. Select SET POINT.

64. Enter 0.25.

65. Select ABOVE SET POINT.

66. Select YES.

67. Select NO.

68. Enter 20.

Continued…

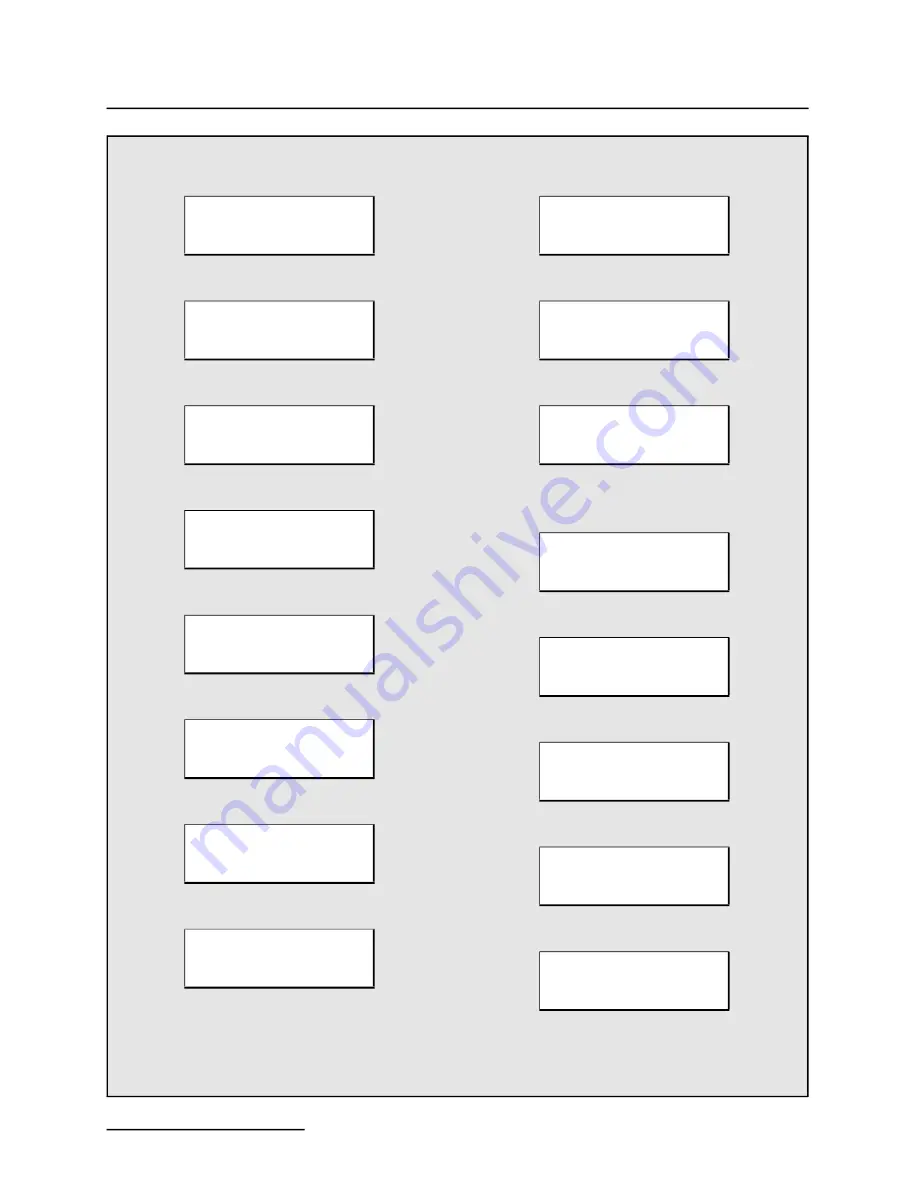

SWITCH BOTTLES ON:

NUMBER OF SAMPLES

TIME

SWITCH BOTTLES EVERY

1

SAMPLES (1- 47)

RUN CONTINUOUSLY?

YES

NO

SAMPLE VOLUME:

500

ml (10-950)

ENABLE:

RAIN

LEVEL FLOW

FR-TEMP ‘A’ DONE

NONE

ENABLE: RAIN

AND

OR DONE

ENABLE: RAIN AND

LEVEL

FLOW ‘A’ DONE

DONE

“RAIN” SET POINT:

0.15

INCHES PER

__HOURS, __MINUTES

ENABLED WHEN:

ABOVE SET POINT

BELOW SET POINT

RESET RAIN HISTORY?

YES

NO

“LEVEL” CONDITION:

SET POINT

RANGE

RATE OF CHANGE

“LEVEL” SET POINT

0.25

ft

(0.100-30.000)

ENABLED WHEN:

ABOVE SET POINT

BELOW SET POINT

ONCE ENABLED,

STAY ENABLED?

YES

NO

SAMPLE AT ENABLE?

YES

NO

START OF SAMPLING

AFTER A

20

MINUTE DELAY

(1-999)

Summary of Contents for Everywhereyoulook BLZZRD

Page 2: ......

Page 4: ......

Page 8: ...BLZZRD Portable Refrigerated Sampler Safety vi ...

Page 16: ...BLZZRD Portable Refrigerated Sampler Table of Contents xiv ...

Page 34: ...BLZZRD Portable Refrigerated Sampler Section 1 Introduction 1 18 ...

Page 58: ...BLZZRD Portable Refrigerated Sampler Section 2 Installation Preparation 2 24 ...

Page 72: ...BLZZRD Portable Refrigerated Sampler Section 3 Programming Introduction 3 14 ...

Page 88: ...BLZZRD Portable Refrigerated Sampler Section 4 Standard Programming 4 16 ...

Page 219: ...BLZZRD Portable Refrigerated Sampler Appendix B Material Safety Data Sheets B 8 ...

Page 233: ...BLZZRD Portable Refrigerated Sampler Appendix D Replacement Parts D 6 ...

Page 241: ...BLZZRD Portable Refrigerated Sampler Appendix F Battery Selection Guide F 4 ...