12

Advanced Installation

This section supplements the basic installation that begins on page 6.

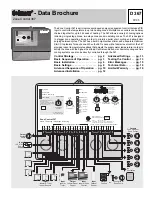

Sensor and Unpowered Input Connections

Do not apply power to these terminals as this will damage the control.

Floating Action RTU and Indoor Sensor Connections

It is best to start the Floating Action heating zones at output relays

1 and 2 and work

towards output relays

5 and 6.

Common Block for

RTU 1 and RTU 2

If the

Com 1-2 (19) common block is used for a floating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 2 (5 and 7).

Common Block for

RTU 3 and RTU 4

If the

Com 3-4 (22) common block is used for a floating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 4 (8 and 10).

Common Block for

RTU 5 and RTU 6

If the

Com 5-6 (25) common block is used for a floating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 6 (11 and 13).

Output Connections

Ventilation

If the DIP switch is set to

Zone 2 Ventilating, connect the 24 V (ac) or 120 V (ac) isolation

relay to the

Com 1-2 — 2 (19 and 21) terminals.

Free Cooling

If the DIP switches are set to

Zone 1 Cooling and Zone 2 Ventilating, the wiring diagram

on the previous page can be followed for connecting the free cooling damper(s) and

fan(s) to the control.

Floating Zones

Common Block

Com 1-2

If the

Com 1-2 common block is used to control a floating action zone valve, wire one

side of the 24 V (ac) circuit to terminal

Com 1-2 (19). The output relay 1 (terminal 20)

is then connected to the open terminal on the actuating motor and the output relay

2 (terminal 21) is connected to the close terminal on the actuating motor.

Common Block

Com 3-4

If the

Com 3-4 common block is used to control a floating action zone valve, wire one

side of the 24 V (ac) circuit to terminal

Com 3-4 (22). The output relay 3 (terminal 23)

is then connected to the open terminal on the actuating motor and the output relay

4 (terminal 24) is connected to the close terminal on the actuating motor.

Common Block

Com 5-6

If the

Com 5-6 common block is used to control a floating action zone valve, wire one

side of the 24 V (ac) circuit to terminal

Com 5-6 (25). The output relay 5 (terminal 26)

is then connected to the open terminal on the actuating motor and the output relay

6 (terminal 27) is connected to the close terminal on the actuating motor.

Test the Outputs

Test the sensors, power supplies, system pump, cooling and on / off zones according to the procedure given on page 9.

Ventilation

If output relay

2 is used to control a ventilation system, make sure power to the ventilation unit is off and install a jumper between

the terminals

Com 1-2 — 2 (19 and 21). When the ventilation circuit is powered up, the ventilation system should turn on. If it does

not, check the wiring between the terminals and the ventilation unit and refer to any installation or troubleshooting information

supplied with the fan.

Free Cooling

If output relays

1 and 2 are used to control a fan and damper, make sure power to the free cooling system is off and install jumpers

between the terminals

Com 1-2 — 1 (19 and 20) and Com 1-2 — 2 (19 and 21). When the circuit is powered up, the free cooling

system should turn on. If it does not, check the wiring between the terminals and relays and also check the wiring to the fan and

damper. Refer to any installation or troubleshooting information supplied with these devices.

19

20

21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

RTU

5

12

13

RTU

6

11

Com

Sen

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

26 27

5

6

25

Com

5-6

Com

Sen

5 6

RTU

1

11

Com

Sen

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

23 24

3

4

22

Com

3-4

19

20 21

1

Com

1-2

2

Com

Sen

5

6

RTU

1

11

Com

Sen

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6