8

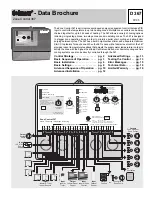

Sen — RTU 4 (8 and 10) terminals.

Common block for

RTU 1 and RTU 2

DIP switch set to Zone 1 Heating

• If the common block is used for a single One Stage heating zone, connect the RTU or Indoor Sensor to terminals

Com Sen

—

RTU 1 (5 and 6).

• If the common block is used for 2 One Stage heating zones, connect one RTU to the

Com Sen — RTU 1 (5 and 6) terminals

and connect the other RTU to the

Com Sen — RTU 2 (5 and 7) terminals.

DIP Switch set to Zone 1 Cooling

• If the 367 is used to enable a cooling system, then no RTU or Indoor Sensor is

connected to terminal

Com Sen — RTU 1 (5 and 6).

• If the 367 is used to control a cooling system the cooling RTU is connected to

terminals

Com Sen — RTU 1 (5 and 6).

• If a single stage heating zone is connected to output relay

2, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 2 (5 and 7).

Two Stage RTU and Indoor Sensor Connections

It is best to start the Two Stage heating zones at output relays

1 and 2 and work towards

output relays

5 and 6.

Common Block for

RTU 1 and RTU 2

• If the common block is used for a Two Stage heating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 2 (5 and 7).

Common Block for

RTU 3 and RTU 4

• If the common block is used for a Two Stage heating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 4 (8 and 10).

Common Block for

RTU 5 and RTU 6

• If the common block is used for a Two Stage heating zone, connect the RTU or

Indoor Sensor to terminals

Com Sen — RTU 6 (11 and 13).

Output Connections

System Pump

Connect the live (L) side of the 120 V (ac) pump circuit through the

System Pmp —

System Pmp (1 and 2) terminals. The control closes a dry relay contact between these

terminals when operation of the system pump is required.

Zone Pumps and Valves

Note

Do not connect a zone pump and zone valve circuit to the same

Com terminal.

• If relay

5 is used, connect the zone pump or zone valve circuit to the Com 5-6 — 5

(25 and 26) terminals on the control.

• If relay

6 is used, connect the zone pump or zone valve circuit to the Com 5-6 — 6

(25 and 27) terminals on the control.

• If relay

3 is used, connect the zone pump or zone valve circuit to the Com 3-4 — 3

(22 and 23) terminals on the control.

• If relay

4 is used, connect the zone pump or zone valve circuit to the Com 3-4 — 4

(22 and 24) terminals on the control.

• If relay

1 is used for heating (DIP switch set to Zone 1 Heating), connect the zone

pump or zone valve to the

Com 1-2 — 1 (19 and 20) terminals on the control.

• If relay

2 is used, connect the zone pump or zone valve circuit to the Com 1-2 — 2

(19 and 21) terminals on the control.

Cooling System

If relay

1 is used for cooling (DIP switch set to Zone 1 cooling), connect the wires from

the cooling unit isolation relay to terminals

Com 1-2 —1 (19 and 20) on the control. The

367 closes a dry relay contact between these terminals when cooling is required.

STEP FIVE

TESTING THE WIRING

Each terminal block must be unplugged from its header on the control before power

is applied for testing. Pull straight down to unplug the terminal block.

The following tests are to be performed using standard testing practices and procedures

and should only be carried out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 — 200 V (ac) and at

least 0 — 2,000,000 Ohms, is essential to properly test the wiring and sensors.

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5

6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

19 20 21

1

22

23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19 20 21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

3

1 2

N

L

Pmp

4

Power

Pmp

System

12 13 14

16

15

17 18

Com

Sen

UnO

Sw

Out

Sen

RTU

5

RTU

6

Zo

Out

Zo

In

19 20

21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

19

20

21

1

22 23

3

4

25

5

26

24

Com

5-6

27

Com

1-2

2

Com

3-4

6

Com

Sen

UnO

Sw

5

6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5