15

STEP NINE

BEFORE YOU LEAVE

• Make sure the wiring safety dividers are installed in their proper locations between compartments with different voltages.

• Install the wiring cover over the wiring chamber and secure it to the base with the two screws provided. Place the front cover on the

control and snap it into place. Install a lock if security is required.

• A sticker has been provided with the control. It is designed to be placed over the Zone 1 ... Zone 6 words

so that the zone names can be written onto the control.

• Place this brochure, and all other brochures relating to the installation, in the protective plastic bag supplied

with the control.

• Place the bag in a conspicuous location near the control for future reference.

• It is important to explain the operation of the control to the end user and to anyone else who may be operating

the system.

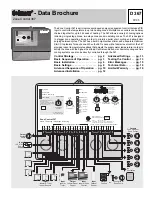

Error Messages

Whenever a fault is detected in any of the sensors and / or room temperature units (RTUs), the indicator lights will flash in specific ways,

to indicate the location of the problem. For detailed Sensor and RTU testing instructions see Data Brochures D 070 and D 054.

RTU 4 Temperature sensor missing RTU 5 Temperature sensor missing RTU 6 Temperature sensor missing

Light on continually

Light flashing

Light off

RTU 3 Temperature sensor missing

Zo — in short circuit

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Outdoor sensor open circuit

(design out

≠

off)

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

RTU 1 short circuit

RTU 2 short circuit

RTU 3 short circuit

RTU 4 short circuit

RTU 5 short circuit

RTU 6 short circuit

RTU 1 Temperature sensor missing RTU 2 Temperature sensor missing

Outdoor sensor short circuit

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

Internal fault

Power

Heat Required

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

5

Zone 5 / Lo stage /

Open

Zone 6 / Hi stage /

Close

6

4

Zone 4 / Hi stage /

Close

3

Zone 3 / Lo stage /

Open

2

Zone 2 / Hi stage /

Close / Ventilation

Zone 1 / Lo stage /

Open / Cooling

1

Kitchen

Living Room

Bedroo

m 1

Bedroo

m

2

Family

Ro

om

Ba

se

m

en

t