7

be installed at a later time.

Power must not be applied to any of the wires during the rough-in wiring stage.

•

Optional If an Outdoor Sensor 070 is used, install it according to the instructions in the Data Brochure D 070 and run two wires back

to the control.

• If an Indoor Sensor 076 is used for any zone, install the Indoor Sensor(s) according to the instructions in the Data Brochure 070

and run the wiring back to the control.

• If an RTU 054 is used, install the RTU(s) according to the installation instructions provided in the Data Brochure D 054 and run the

wiring back to the control.

• If multiple Zone Controls are used, run two wires from one Zone Control to the next to create a chain.

• Run wires from the 120 V (ac) power to the control.

Use a clean power source to ensure proper operation. Multi-strand 16 AWG

wire is recommended for all 120 V (ac) wiring due to its superior flexibility and ease of installation into the terminals.

• Run wiring from the system pump to the control.

• Run wires from each zone valve / pump to the control.

STEP FOUR

ELECTRICAL CONNECTIONS TO THE CONTROL

The installer should test to confirm that no voltage is present at any of the wires. Push the

control into the base and slide it down until it snaps in firmly.

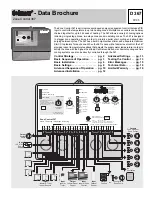

Powered Input Connections

120 V (ac) Power

Connect the 120 V (ac) power supply to terminals

Power N — L (3 and 4).

Sensor and Unpowered Input Connections

Do not apply power to these terminals as this will damage the control.

Outdoor Sensor

Connect the two wires from the Outdoor Sensor 070 to the terminals

Com Sen — Out

Sen (16 and 18). The Outdoor Sensor measures the outdoor air temperature.

Zone Control Input and Output

Connect a wire between the

Com Sen (16) terminals on each 367. Connect the Zo Out

terminal on the first 367 to the

Zo In terminal on the second 367. With several Zone

Controls, connect the

Zo Out terminal on the second 367 to the Zo In terminal on the

third 367 and continue this process for each additional 367. The

Zo Out terminal on the

last 367 in the chain can be connected to the

Zo In terminal on a tekmar reset control.

Note The wires from the Zone Control are polarity sensitive. The system will not

operate if the wires are reversed.

UnOccupied Switch

If an external timer or switch is used, connect the two wires from the external dry contact

switch to the

UnO Sw — Com Sen(14 and 16) terminals. When these terminals short

together, the control registers an UnOccupied signal.

Note If an external switch is closed between the terminals

UnO Sw — Com Sen

(14 and 16), the 24 hr. Timer is disabled and the Optimum Start / Stop

information is lost. It is recommended that either the 24 hr. Timer or an external

timer / switch is used, not both at the same time.

One Stage RTU and Indoor Sensor Connections

RTUs and Indoor Sensors provide indoor temperature feedback to the control. It is best

to start the One Stage zones at output relay

5 and work towards output relay 1.

Common block for

RTU 5 and RTU 6

• If the common block is used for a single One Stage heating zone, connect the RTU

or Indoor Sensor to terminals

Com Sen — RTU 5 (11 and 12).

• If the common block is used for 2 One Stage heating zones, connect one RTU or

Indoor Sensor to the

Com Sen — RTU 5 (11 and 12) terminals and connect the

other RTU or Indoor Sensor to the

Com Sen — RTU 6 (11 and 13) terminals.

Common block for

RTU 4 and RTU 3

• If the common block is used for a single One Stage heating zone, connect the RTU

or Indoor Sensor to terminals

Com Sen — RTU 3 (8 and 9).

• If the common block is used for 2 One Stage heating zones, connect one RTU to

the

Com Sen — RTU 3 (8 and 9) terminals and connect the other RTU to the Com

3

1 2

N

L

Pmp

4

Power

Pmp

System

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5

Com

Sen

UnO

Sw

5 6

RTU

1

12

RTU

6

11

13

Com

Sen

Com

Sen

14

16

Zo

In

15

17

Zo

Out

RTU

2

7

RTU

3

9

RTU

4

10

8

Com

Sen

Out

Sen

18

RTU

5