3

At the start of the night setback period the heat is turned off, but the heat

contained within the slab or radiator continues to heat the building and

there is a delay before the space temperature begins to drop. At the end

of this delay the temperature within the building gradually decreases, and

may eventually reach the required UnOccupied temperature after suffi-

cient time has elapsed. Once the setback period is complete, the heat is

turned on again but there is a long recovery time required to raise the

space temperature to the desired setpoint. The length of the delay and

recovery periods changes with outdoor temperature and is different for

each zone within the building.

A comfortable setback can be provided if the control “learns” the

response time for each zone within the building. Based on the zone’s

response time, the control can then calculate an Optimum Stop time and

an Optimum Start time. At the Optimum Stop time the control turns off the

zone valve or pump in order to overcome the delay period and at the

Optimum Start time, the control starts to raise the zone temperature in

order to overcome the recovery period. This allows night setback to be

used with most heating systems.

Optimum Start / Stop with Water Temperature Boost

When Optimum Start / Stop is combined with Outdoor Reset, the

control can boost the water temperature during the recovery period.

This provides a faster recovery and allows a longer setback for greater

energy savings.

The accuracy of the Optimum Start / Stop routine depends on the

feedback available to the control.

Optimum Start / Stop with both Outdoor and Indoor Sensors

The response time of the building varies with outdoor temperature and is also different

for each zone. The most accurate Optimum Start / Stop routine is therefore achieved

when both the indoor and outdoor temperatures are monitored during transitions between

UnOccupied and Occupied modes.

Optimum Start / Stop with only Indoor Sensors

When only indoor temperature feedback is available, the control must base all Optimum

Start / Stop calculations on

indoor temperature only. If there are large variations in outdoor

temperature, this method cannot provide the same level of accuracy as when both indoor

and outdoor sensors are used.

Optimum Start / Stop with only an Outdoor Sensor

Every building, and often each zone within the building, has a different response time.

When only an outdoor sensor is used, the control must assume a particular response time

for the entire building. Therefore this is generally the least accurate method of calculating

Optimum Start / Stop times.

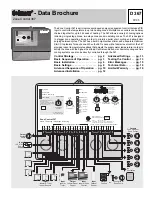

Basic Sequence of Operation

To use the basic features of the control, the DIP switches must be set to

One & Two Stage and Zone 2 Heating and the Design Outdoor dial must

be set to Off . More advanced features including modulating zones, free

cooling and demand limiting are explained on page 10.

POWERING UP THE CONTROL

After the Zone Control 367 is powered up, a software version code is displayed for 2 seconds

and then the red indicator lights are then turned on for 4 seconds. When the control is

powered up, the green

Power light remains on continuously. For the first fifteen minutes

after power up, the

Test light flashes and the control responds immediately to changes of

settings. This allows the installer to test the operation of the system. After fifteen minutes,

the control enters its normal operating mode in which reactions to setting changes are

significantly slower. A slower reaction time to setting changes allows the control to provide

a more stable room temperature.

Only in the first 15 minutes after power up, does

the control respond immediatley to settings

adjustments.

70

M

Test

Delay

Period

5 A.M.

9 P.M.

10 P.M.

8 A.M.

Room Temperature

Setback Period

Optimum

Stop

Recovery

Period

Optimum

Start

Occ

70

°

F

(21

°

C)

UnOcc

65

°

F (18

°

C)

Delay

Period

6 A.M.

9 P.M.

10 P.M.

8 A.M.

Room Temperature

Setback Period

Optimum

Stop

Shorter

Recovery

Period

Optimum

Start

UnOcc

65

°

F (18

°

C)

Occ

70

°

F

(21

°

C)

Delay

Period

8 A.M.

10 P.M. 11 P.M.

11 A.M.

Recovery

Period

Setback Period

Occ

70

°

F (21

°

C)

UnOcc

65

°

F

(18

°

C)

Zone 2 Heating

One & Two Stage

0

°

F

-40

Off

Design Outdoor

30

Outdoor

Sensor

Room

Temperature

Units (RTU's)

Room

Temperature

Units (RTU's)

Outdoor

Sensor