10

Floating Motor Speed

This dial has no effect on the operation of the control unless modulating zone valves are

used. See the Advanced section of this brochure for more information.

Using the Internal 24 hr. Timer

First determine the length of time required for the UnOccupied period and turn the

UnOccupied Duration dial to the desired duration length. If the dial is set to 24 hours, the

370 remains in UnOccupied mode continuously. If the dial is set to 0 hours, the 370

remains in Occupied mode continuously.

Press the

Start button at the desired starting time for the UnOccupied period. Once the

Start button is pressed, the 370 enters the UnOccupied period at the same starting time

each day.

Example The user wants an UnOccupied period starting at 10 pm and ending at 6 am.

The

Unoccupied Duration dial is set to 8 hours and the Start button is pushed at

10 pm. Once the

Start button is pushed, the control goes into UnOccupied mode

from 10 pm until 6 am the next morning. This cycle is repeated 7 days a week.

DIP Switch Settings

Occ / UnOcc — Occ. Only

Each zone can be selected to operate in either Occupied only mode or both Occupied

and UnOccupied modes. If the DIP switch is set to

1,2 Occ. only, the zones connected

to relays

1 and 2 remain in the Occupied mode at all times. If the DIP switch is set to

1,2 Occ / UnOcc, zones 1 and 2 are switched into UnOccupied mode each time the 367

receives an UnOccupied signal. Zones

3, 4, 5 and 6 can be individually selected for

Occupied only or both UnOccupied and Occupied mode operation. If Two Stage zones

are used, the DIP switches for both output relays should be set to the same postion.

Optimum Start

The Optimum Start / Stop feature is used during transitions between the UnOccupied

mode (Night Setback) and the Occupied mode. When the DIP switch is set to

Optimum

Start, the 367 raises the building temperature during the final stages of the UnOccupied

period. This helps ensure the building is at the Occupied temperature as soon as the

Occupied period begins. If the

Optimum Start DIP switch is set to Off, the 367 does not

start raising the building temperature until the UnOccupied period ends. More informa-

tion on the Optimum Start feature is provided on page 2 of this brochure.

Thermal Motor

Zone valves with thermal actuating motors have long opening and closing times. In

order for the 367 to compensate for these longer times, the DIP switch should be set

to

Thermal Motor. If fast acting electric motor zone valves or zone pumps are used, the

DIP switch must be set to

Off.

One Stage & Floating / One & Two Stage

This DIP switch must be set to the

One & Two Stage position unless modulating zones

are used. See the Advanced section of this brochure for more information.

Zone 1 Cooling / Zone 1 Heating

The zone

1 relay can be used to control a heating zone or to enable or control a cooling

system. If zone

1 is to be used for heating, the DIP switch must be set to Zone 1 Heating.

If zone

1 is used for cooling, the DIP switch must be set to Zone 1 Cooling.

Zone 2 Ventilating / Zone 2 Heating

This DIP switch must be set to the

Zone 2 Heating position unless ventilation or free

cooling is desired. See the Advanced section of this brochure for more information.

Advanced Sequence of Operation

A thorough understanding of the basic features of this control should be obtained before

reading the advanced section.

MODULATING ZONES

When the DIP switch is set to

One Stage & Floating, the 367 can control up to 6 One Stage

zones or 3 Floating Action zones or a combination of single stage and floating zones.

Floating zones allow the control to operate modulating zone valves.

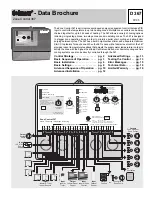

UnOccupied

Duration

Timer Active

24 hr. Timer

• Dial the desired duration of the

UnOccupied period.

• Press start button at the time of day

you want the UnOcc. period to begin.

Timer Active light turns on.

Start

0 = always Occupied

24 = always UnOccupied

0

12 hrs.

24

6

18

UnOccupied

Duration

Floating Motor

Speed

130 sec.

30

230

100

200

Zone 2 Ventilating

Zone 2 Heating

Zone 1 Heating

Zone 1 Cooling

Off

Thermal Motor

Off

Optimum Start

Zone

Occ/UnOcc

1,2

4

3

Occ. only

5

6

One Stage & Floating

One & Two Stage

One Stage & Floating