11

Common Blocks

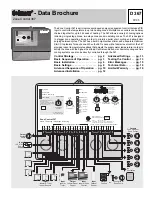

The 367 has 3 common blocks for both the RTU inputs and relay outputs. Each common block has a terminal starting with

Com

(e.g.

Com Sen or Com 1-2 ). When the DIP switch is set to One Stage & Floating, each common block can be used for either two

One Stage zones or one Floating action zone. One Stage common blocks are explained on page 4 of this brochure.

Floating Action Common Blocks

When the DIP switch is set to

One Stage & Floating and a single RTU is connected to the highest terminal

number in the common block, a Floating Action zone is created. The single RTU controls two relay outputs

- an

Open relay and a Close relay. The Motor Speed dial is used to set the time required for the floating action

actuating motor to go from fully closed to fully open.

Example An RTU connected between the terminals

Com Sen — RTU 2, is used to control the output relays

1 and 2. Relay 1 is the Open relay and relay 2 is the Close relay.

Each floating zone is controlled by repositioning the floating action valve every 15 minutes

based on the space temperature in the zone. The control uses PID logic to maintain an

accurate space temperature. When the measured space temperature is above or below

the desired setpoint, the 367 calculates a new position for the valve and then operates

the

close or open relay in order to achieve the new position. The floating action output is

designed for either linear modulating injection valves that change the supply water

temperature to the terminal unit or equal percentage modulating valves that change the

flowrate through the terminal unit.

VENTILATION

The 367 can be used to operate a ventilation system. When the DIP switch on the 367 is

set to

Zone 2 Ventilating, the 367 ignores the RTU 2 terminal and utilizes the output relay

2 to operate the ventilation system. During the Occupied period, the output relay 2 is turned

on, and during the UnOccupied period the output relay

2 is turned off. The ventilation system

is therefore only operated during occupied periods in order to conserve energy. If

Optimum

Start is selected, the 367 starts the ventilation system one hour before the Occupied period

begins. This allows sufficient time to purge the air for normal occupancy.

FREE COOLING

If the DIP switches are set to both

Zone 1 Cooling and Zone 2 Ventilating,

the 367 can operate a fan and damper to bring outside air into the building

for free cooling. An Indoor Sensor or RTU must be connected between

terminals

Com Sen — RTU 1 and an Outdoor Sensor must be connected

to

Com Sen — Out Sen. Whenever cooling is needed and the heating

zones have been satisfied for at least 45 minutes and the outdoor air

temperature is at least 3

°

F colder than the indoor air temperature, the 367

turns on relays

1 and 2 together. The 367 varies the on time of output

relays

1 and 2 over a 30 minute period. As the cooling load increases, the

on time of the output relays increases.

Combining Ventilation, Free Cooling & Mechanical Cooling

All three systems (ventilation, free cooling and mechanical cooling)

can be operated through the appropriate wiring, as shown in the

adjacent diagram. When the 367 is used to operate all three systems,

the output relay

2 (ventilation) is turned on during occupied periods

whenever cooling is not being done. The 367 operates both output

relay

1 and output relay 2 (free cooling) when cooling is required and

the outdoor temperature is below the desired indoor temperature.

When the outdoor temperature is warmer than the desired indoor

temperature, the 367 turns off output relay

2 and turns on output relay

1 in order to run the mechanical cooling system.

DEMAND LIMITING (

Design Outdoor dial)

The heat supplied to the zones can be limited based on outdoor temperature. Demand Limiting is an energy

saving function that is used to prevent excessive energy consumption when there is an unnecessary heating

load such as an open window during moderate outdoor conditions. This function should only be used if the 367

is not connected to a tekmar reset control. When the

Design Outdoor dial is turned up from the Off position

and an outdoor sensor is present, the demand limiting function is enabled. Based on the outdoor temperature,

the control restricts the maximum on time of the zone relays. The control allows a full 15 minute on time when

the outdoor temperature reaches the temperature set on the

Design Outdoor dial. Above this temperature the

maximum on time is reduced until the outdoor temperature reaches the WWSD point where the maximum on

time is zero.

H

C

R

N

C

Floating Zone

Com

1-2

19

1

20

2

21

Com

Sen

5

6

RTU

1

RTU

2

7

Floating Motor

Speed

130 sec.

30

230

100

200

3

4

6

5

7

2

1

8

3

4

6

5

7

2

1

8

M

M

Cool

24 V (ac)

120 V (ac)

N

L

C

R

Zone 1 Cooling

Zone 2 Ventilating

Damper

motor

Fan

2

21

1

20

19

Com

1-2

Zone 2 Ventilating

0

°

F

-40

Off

Design Outdoor

30