5

Fast Acting Zone Valves or Zone Pumps

If the

Thermal Motor DIP switch is set to Off, the 367 assumes that fast acting zone valves

or zone pumps are connected to the zone relays. The system pump and

Heat Required

light are therefore turned on as soon as the first zone relay is operated. One minute before

the last zone relay is turned off, the 367 purges the boiler by turning the

Heat Required

light off and keeping the system pump operating.

Slow Acting Zone Valves with Thermal Motors

When the DIP switch is set to

Thermal Motor, the 367 assumes that slow acting zone

valves with thermal actuating motors are connected to the zone relays. With slow acting

zone valves, the 367 allows a 3 minute period for the first zone valve to open before the

system pump and

Heat Required light are turned on. The total operating time for the zone

relays is also increased by an extra 2 minutes. This helps compensate for the longer

opening versus closing time of the slow acting zone valves. For one minute after the last

zone relay is turned off, the 367 purges the boiler by turning the

Heat Required light off

and keeping the system pump operating.

COOLING OPERATION

When the DIP switch on the 367 is set to

Zone 1 Cooling, output relay 1 can either be used

to enable an auxiliary cooling control system or to directly operate a central cooling unit.

Cooling Control (RTU is present)

If

Zone 1 Cooling is selected and an RTU or Indoor Sensor is connected to terminals Com

Sen — RTU 1 (5 & 6), the 367 can directly control a central mechanical cooling system

using output relay

1. If an RTU is used, the desired indoor temperature is set using the

RTU dial down to 73

°

F (23

°

C), but if an Indoor Sensor is used, the desired indoor

temperature is fixed at 77

°

F (25

°

C). Output relay

1 is allowed to turn on once the heating

zones connected to the 367 have been satisfied for at least 45 minutes, and is turned off

whenever any zone requires heat. The 367 varies the on time of output relay

1 over a 30

minute period. As the cooling load increases, the on time of the output relay increases.

In order to prevent short cycling, the 367 ensures that the output relay remains on or off

for at least 3 minutes.

Cooling Enable (No RTU)

If

Zone 1 Cooling is selected and there is no RTU or Indoor Sensor connected to terminals

Com Sen — RTU 1 (5 & 6), the 367 can enable an auxiliary cooling control through output

relay

1. Output relay 1 is turned on once the heating zones connected to the 367 have

been satisfied for at least 45 minutes, and is turned off whenever any zone requires heat.

UNOCCUPIED (NIGHT SETBACK)

The 367 can be switched into UnOccupied mode through the built in 24 hr. Timer or by

closing an external switch or timer relay wired between the terminals

UnO Sw — Com Sen

(14 & 16) on the control.

24 hr. Timer

The 367 has a built in 24 hr. Timer which can be used to set a single UnOccupied event

during a 24 hour period. The 24 hr. Timer is activated by pushing the

Start button at the

desired starting time for the UnOccupied period. The duration of the UnOccupied period

is set using the

UnOccupied Duration dial. Once the Start button is pushed, the Timer

Active light is turned on and the 367 enters the UnOccupied mode each day at the same

starting time. The 24 hr. Timer can be deactivated by pressing the

Start button again. A

new UnOccupied period starting time can be selected by repeating the above procedure.

Note If an external switch is closed between the terminals

UnO Sw — Com Sen

(14 & 16), the 24 hr. Timer is disabled. An external UnOccupied switch and the 24

hr. Timer should not be used at the same time.

UnOccupied Switch Input

A switch or external timer with a dry relay contact output can be wired between the

terminals

UnO Sw — Com Sen (14 & 16) on the 367. When the switch or relay contact

is closed, the 367 registers an UnOccupied signal. A tekmar Timer 031 is available which

can be programmed to provide individual UnOccupied schedules for each day of the week

with up to two separate UnOccupied events per day. For more information on the Timer

031 see the Data Brochure D 031.

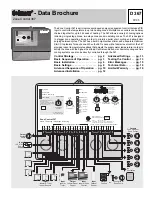

Zone 1 Cooling

Fast acting

zone valve

or zone pump

Off

Thermal Motor

Slow acting

zone valve

Off

Thermal Motor

C

Cooling Control

RTU

Com

1-2

19

1

20

2

21

Com

Sen

5

6

RTU

1

RTU

2

7

C

Cooling Enable

No RTU

Com

1-2

19

1

20

2

21

Com

Sen

5

6

RTU

1

RTU

2

7

SCHD

Su

T I M E

AMPM

UNOCC

OVR

Sa

Mo

WeTh Fr

Tu

1

2

Zo

Out

15

14

UnO

Sw

Com

Sen

16

Occupied

Optimum Start / Stop

UnOccupied

Timer Active

24 hr. Timer

0

12 hrs.

24

6

18

• Dial the desired duration of the

UnOccupied period.

• Press start button at the time of day

you want the UnOcc. period to begin.

Timer Active light turns on.

Start

UnOccupied

Duration

0 = always Occupied

24 = always UnOccupied