14

Step 3 - The control tests relays 3 and 4 using the procedure described in Step 2.

Step 4 - If the DIP switches are set to Zone 1 Heating and Zone 2 Heating, the control tests relays 1 and 2 using the procedure

described in Step 2.

-

If the DIP switch is set to

Zone 2 Ventilating or its is set to Zone 2 Heating and an RTU is connected to RTU 2, the control

turns on relay

2 for 10 seconds.

-

If the DIP switch is set to

Zone 1 Cooling or an RTU is connected to RTU 1 the

control turns on relay

1 for 10 seconds.

Step 5 - After the test sequence is complete, the Test light begins flashing and the control enters a fast mode of operation. During

this time, the control is more responsive to setting adjustments. If the dial on an RTU is turned up, the on time of the zone

relay increases immediately. After fifteen minutes, the control reverts back to normal operating conditions and the on times

are based on the average temperature during the previous 15 minute cycle.

Manual Test

While the control is in the fast mode of operation and the

Test light is flashing, check that

each RTU operates the proper zone valve or zone pump. Turn up the

RTU dial to turn the

zone on, turn the dial down to turn the zone off. If an Indoor Sensor is used, a cold spray

to the sensor will turn the zone on.

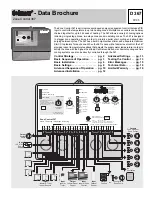

Indicator Lights “On”

Power

• 120 V (ac) power is applied to the control and the control

is energized.

Heat Required

• The 367 is sending a heat required signal to a tekmar reset control. At least one of the heating zones

requires heat.

System Pump

• The relay contact between

System Pmp—System Pmp (1 and 2) is closed and the System Pump should

be turned on.

Zone 1 / Lo Stage /

• The relay contact between

Com 1-2— 1 (19 and 20) is closed and the device connected to this relay

Open / Cooling

should be turned on.

Zone 2 / Hi Stage /

• The relay contact between

Com 1-2— 2 (19 and 21) is closed and the device connected to this relay

Close / Ventilation

should be turned on.

Zone 3 / Lo Stage /

• The relay contact between

Com 3-4— 3 (22 and 23) is closed and the device connected to this relay

Open

should be turned on.

Zone 4 / Hi Stage /

• The relay contact between

Com 3-4— 4 (22 and 24) is closed and the device connected to this relay

Close

should be turned on.

Zone 5 / Lo Stage /

• The relay contact between

Com 5-6— 5 (25 and 26) is closed and the device connected to this relay

Open

should be turned on.

Zone 6 / Hi Stage /

• The relay contact between

Com 5-6— 6 (25 and 27) is closed and the device connected to this relay

Close

should be turned on.

Test

• The control is proceeding through the programmed test sequence.

Occupied

• The control is in Occupied mode.

UnOccupied

• The control is in UnOccupied (Night Setback) mode.

Optimum Start / Stop

• The control is warming the building up during the final stages of the UnOccupied period, or the heating

system is turned off during the final stages of the Occupied period.

Timer Active

• The timer is set to enter the UnOccupied mode every 24 hours at the time of day the

Start button was

pressed.

STEP EIGHT

TROUBLESHOOTING

As in any troubleshooting procedure, it is important to isolate a problem as much as possible before proceeding. The Error Messages

and

Test button greatly simplify troubleshooting of the 367. When the control is flashing an error message, identify the fault from the

look-up table on page 15 and follow standard testing procedures to confirm the problem. If you suspect a wiring fault, return to steps

three, four and five, and carefully check all external wiring and wiring connections.

Sensor and Internal Faults

• If an Outdoor Sensor fault occurs, the 367 operates as if an Outdoor Sensor is not connected. An error message is displayed.

• If an RTU / Indoor Sensor fault occurs or an external Zone Control input

Zo - in short circuits, the 367 operates as if that RTU or

Zone Control is not connected. An error message is displayed.

• If an internal control fault occurs, the 367 displays an error message. Press the

Test button to clear the error message. If the error

message remains, the control must be returned for repair.

Adjusting RTU settings provides an immediate

response for the first 15 minutes only.

70

M

Test