17

The boiler must be positioned and installed by a skilled installer in accordance with all applicable standards and

regulations. Commissioning of the boiler must be done by a skilled service/commissioning engineer, who is trained

for this type of boiler.

6.3 Mounting the boiler

Before mounting and installing the boiler the following connections should be considered:

•

Flue gas system and the flue gas pipe

connections

•

Air supply system and connections

•

Flow and return pipe connection

•

Condensate and pressure relief valve drainage

•

Power supply (preferably the power connection

positioned above the boiler)

•

Gas pipe.

All lines/piping must be mounted free of tension. The weight of the installation components should be

supported separately from the boiler so there will be no standing forces on the connections.

This might influence the mounting position of the boiler.

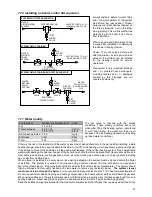

Determine the position of the boiler by using the included suspension bracket or a suspension frame (when

supplied). While marking the holes, ensure that the suspension bracket or frame is perpendicular, and the boiler

does not lean forward. If necessary, adjust the position with the adjusting bolts at the lower rear side of the back

panel (see drawing). When the adjusting bolts aren’t sufficient, fill the gap behind the bolts to get the boiler in

position. The boiler position lies between the boiler hanging level and hanging slightly backwards (min. 0.5° - max

1.5°).

The boiler should not lean forward in the mounted position.

Lock the suspension bracket with

the security cover before making

any other connections to the boiler.

This security cover will prevent the

boiler from falling off the bracket.

Don't use excessive force during

the mounting of the boiler

connections.

3

. Lock boiler with locking plate

and two bolts

2

. Suspend

boiler with

suspension

bracket on

mounting

bracket

1

. Attach mounting bracket to wall

with inclined side facing upwards

4

. Level boiler using

adjusting bolts

suspension

detail

Slightly backwards (min. 0.5° - max 1.5°)

for the condensate to properly drain

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......