45

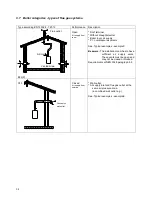

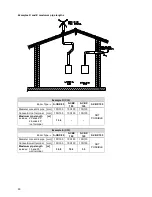

9.13 Typical examples

A

:

Twin pipe system with separate pipes for flue gas and air supply

C63

B

:

Twin pipe system with separate pipes and concentric roof terminal

C33

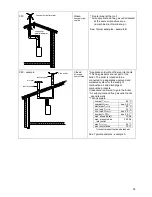

C

:

Single pipe for flue gas outlet only (air supply from boiler room)

B23

D

:

Concentric pipe for flue gas/air supply (roof-mounted)

C33

E

:

Concentric pipe for flue gas/air supply (wall-mounted)

C13

Be Aware: We used the specific resistance values of Strebel Ltd flue gas and air intake parts

for these examples. Other suppliers may have different values!

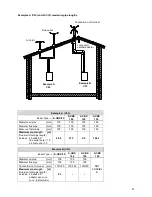

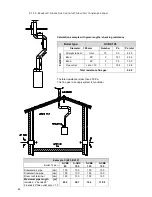

9.13.1 E

XAMPLE

A:

T

WIN PIPE SYSTEM WITH SEPARATE PIPES FOR FLUE OUTLET AND AIR SUPPLY

Calculation example with given lengths: checking resistance

Boiler type:

S-CBX 155

Flue gas

Diameter: 150 mm

quantity

Pa

Pa total

Straight tube /m

total

9

1.1

9.9

Bend

90°

2

4.4

8.8

Flue outlet

zeta=1.0

1

5.6

5.6

Total resistance flue gas outlet:

24.3

A

ir

su

pp

ly

Diameter: 150 mm

quantity

Pa

Pa total

Straight tube /m

total

8

1.3

10.4

Bend

90°

2

5.1

10.2

Air inlet

zeta=1.0

1

6.5

6.5

Total resistance air supply:

27.1

Total resistance flue gas outlet and air supply:

51.4

The total resistance is less than 200 Pa.

This flue gas/ air supply system is functional.

NOTE: Strebel Ltd specific resistance values are used in this example.

Flue and air pipes of other suppliers can have other values

CB 155

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

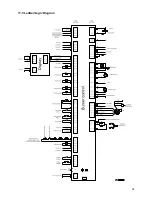

Page 55: ...55 11 5 Ladder Logic Diagram ...

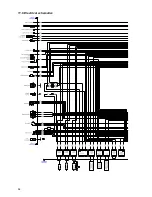

Page 56: ...56 11 6 Electrical schematics ...

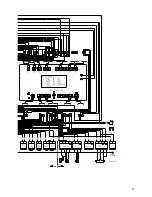

Page 57: ...57 ...

Page 137: ......