3-16

Installing the Servo Drive

07-01-08-02-E-V0500 631 Digital Servo Drive

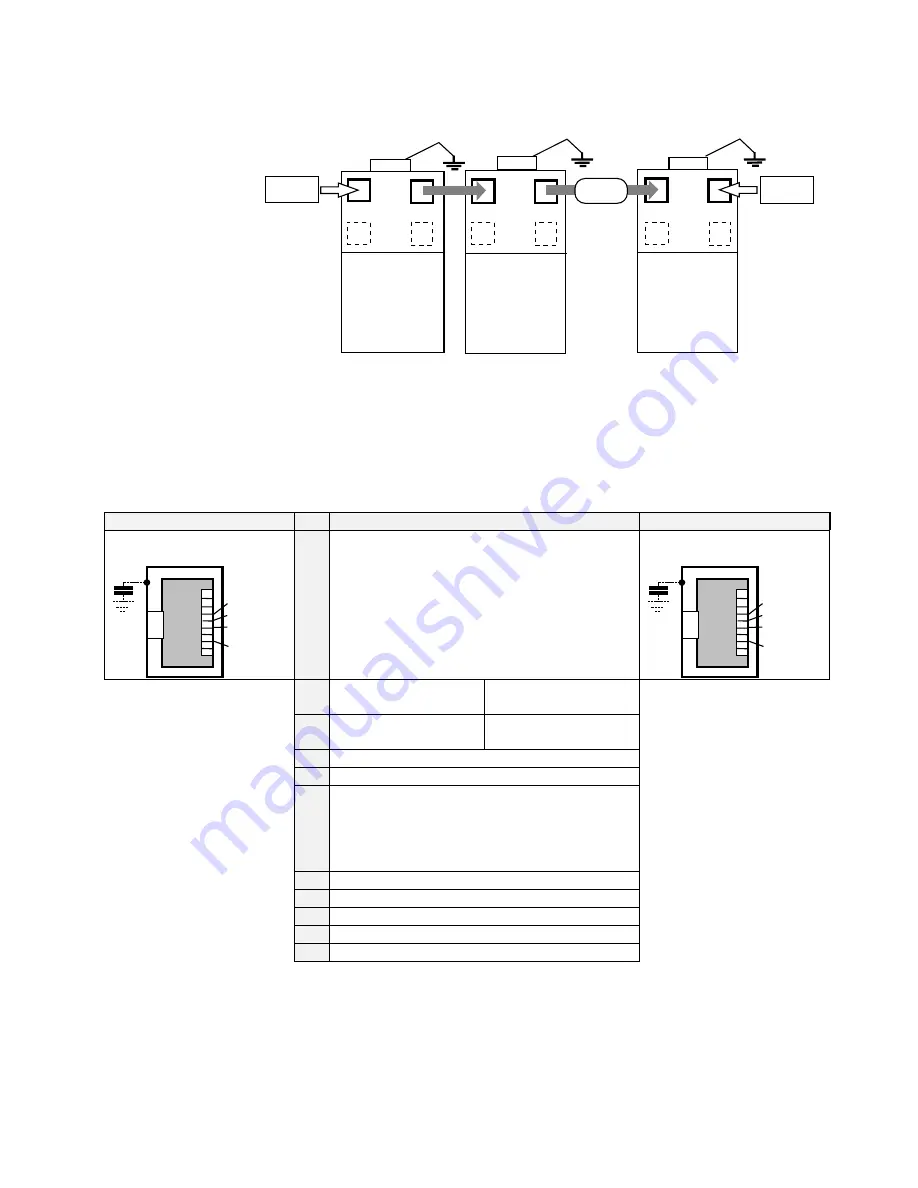

X20/21 - CAN-Bus Digital Interface Connections

Standard fieldbus protocol CAN-Bus interface.

631

631

NODE 2

LAST NODE

GND

GND

GND

631

NODE 1

X20

X21

X20

X21

X20

X21

124 Ohm

124 Ohm

CAN-Bus

Bus

Termination

Bus

Termination

To network several 631 servo drives, connect the X20/21 sockets as shown using the specified

cables. The 631 is configured using EASYRIDER software

<

.

Note:

The daisy-chain wiring is intended to be used for local bus distribution. Long bus

extensions should not cross daisy-chain sections.

Refer to Chapter 11: “Control and Communications” for cabling details.

X20

X20

X20

X20

Pin

Pin

Pin

Pin Function

Function

Function

Function

X21

X21

X21

X21

8-pole Modular Jack,

screened

1

8

CAN_GND

CAN_L

CAN_H

GND

CAN_GND

X20 and X21 are identically and internal

switched in parallel with all pins, (X20 = X21)

therefore bus-wiring is very easy.

8-pole Modular Jack,

screened

1

8

CAN_GND

CAN_L

CAN_H

GND

CAN_GND

internal connection to

GND via capacitor

Case: Screened

Operating Conditions

and Protocol

See documentation

7.5.3.x

1

11

1

2

22

2

3

33

3

CAN_GND

reference

galvanically separated.

Coupling-resistor to

PE / GND: 1M

Ω

4

44

4

CAN_L (dominant low)

5

55

5

CAN_H (dominant high)

6

66

6

7

77

7

CAN_GND, like Pin 3

8

88

8

This Pin Assignment is related to “CiA Draft Recommendation DR-303, V0.1 / 26.10.98”.

The wires on Pins 3/6 and 4/5 should be twisted pairs.

A defined quiescence level on the bus must be guaranteed for communication. You should use

terminal resistors on both ends of the line. Use special bus plugs that have a resistance of

approximately 124

Ω

between CAN_L and CAN_H.

Note:

A plug with an internal terminal resistor is available see Chapter 9: “Accessories”.