Hydraulic connection

28

Installation manual

thermi

nator

II touch

Overall output of heat supply

German hard-

ness

Specific water content of the system <20 l / kW

≤ 50 kW

≤ 16.8 °dH

> 50 kW to ≤ 200 kW

≤ 11.2 °dH

> 200 kW to ≤ 600 kW

≤ 5.6 °dH

> 600 kW

≤ 2.8 °dH

Specific water content of the system ≥ 20 l/kW, but

< 50 l/kW

≤ 50 kW

≤ 11.2 °dH

> 50 kW to ≤ 200 kW

≤ 5.6 °dH

> 200 kW to ≤ 600 kW

≤ 2.8 °dH

> 600 kW

≤ 0.6 °dH

Specific water content of the system ≥ 50 l/kW

≤ 50 kW

≤ 5.6 °dH

> 50 kW to ≤ 200 kW

≤ 2.8 °dH

> 200 kW

≤ 0.6 °dH

In the event of exceeding the above values, the fill-up

water is to be treated. Recommended action: Soften-

ing (e.g., ion-exchange resin, the same procedure as

for drinking water softening).

Check the pH of the fill-up water

- In the normal case (mixed installation) no

measures are required to influence the pH (control:

value should be in the range of 8.2 to 10).

- Exception: If aluminium materials are used in the

heating system, a pH from 8.2 to 8.5 must be met

(pH> 8.5 increased corrosion tendency).

- If the value is significantly less than <8.2 after fill-

ing, then check again after 8-12 weeks

- If there is no increase in value, then add 10 g/m³

trisodium phosphate (Na3PO4) or 5 g/m³ sodium

hydroxide (NaOH).

Allow 2-4 weeks of operation before further correc-

tions.

Electrical conductivity

Recommendation: Low salt driving (filling with de-

mineralised water), see VDI 2035 sheet 2.

Low salt

Salty

Electrical conductivity

at 25°C

< 100

µS/cm

100

– 1500

µS/cm

Compliance with the above mentioned stand-

ards/regulations must be ensured by the heat-

ing engineer.

Manufacturer's requirements for high-efficiency

heat pumps: > The heater water must meet the

specifications of standard VDI 2035.

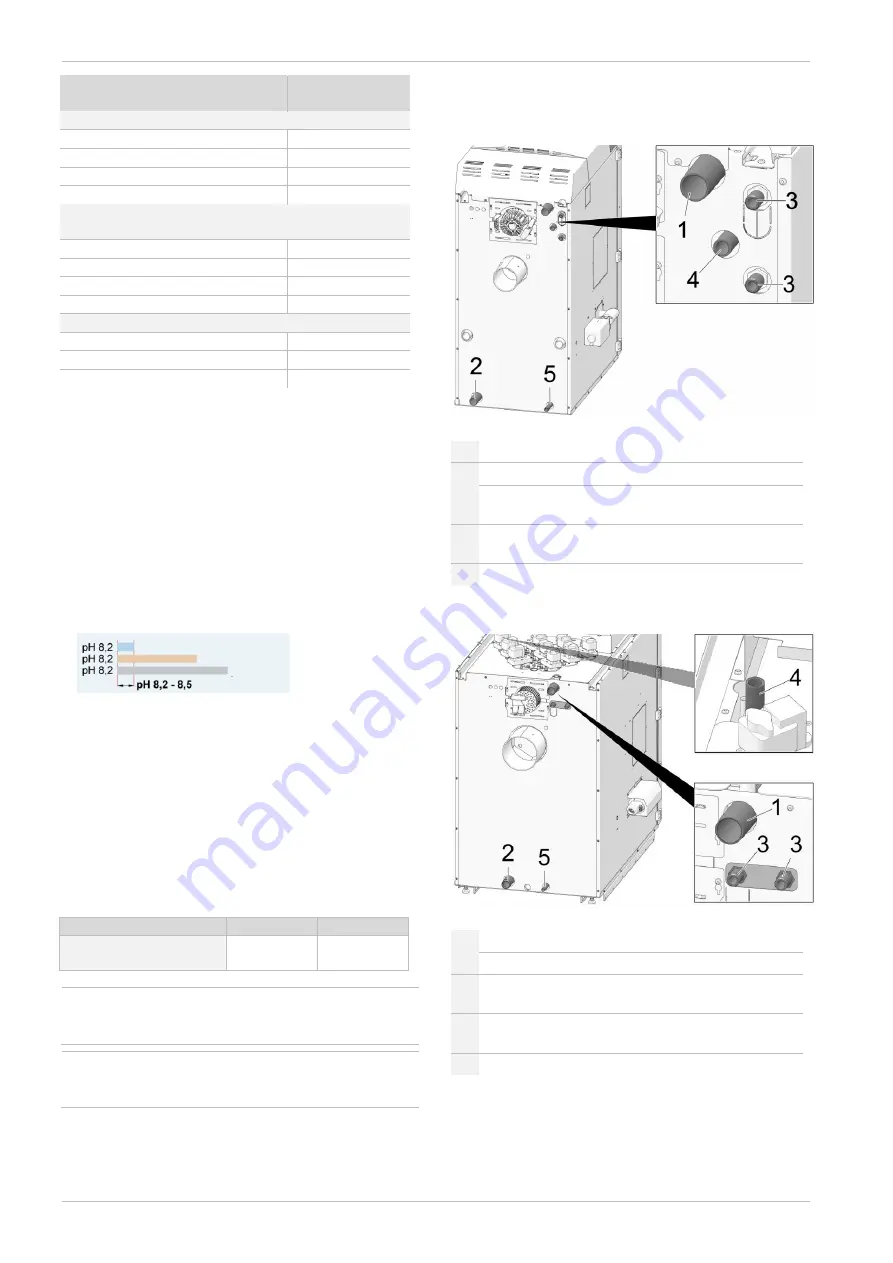

6.3 Boiler connections

thermi

nator

II 18 up to 30

Fig. 6-1_001cCP

1 Boiler flow

2 Boiler return

3

Connections for the thermal overload protection

(1/2” external thread)

4

Immersion sleeve for the sensor of the thermal

overload protection

5

Boiler drain point (1/2“ OT)

thermi

nator

II 36 up to 60

Fig. 6-2_002cBY

1 Boiler flow

2 Boiler return

3

Connections for the thermal overload protection

(1/2” external thread)

4

Immersion sleeve for the sensor of the thermal

overload protection (below the boiler cover)

5

Boiler drain point (1/2“ OT)

pH 8.5 Aluminium

pH 9.5 Copper

pH 10 Steel

Summary of Contents for Therminator II

Page 39: ...Annex Installation manual therminator II touch 39 9 6 Commissioning log ...

Page 40: ...Annex 40 Installation manual therminator II touch ...

Page 41: ...Annex Installation manual therminator II touch 41 9 7 Customer service order form ...

Page 42: ...Annex 42 Installation manual therminator II touch ...

Page 43: ...Annex Installation manual therminator II touch 43 ...