1 2 3

ON

1 2 3

ON

1 2 3

ON

1 2 3

ON

ON

1 2 3

1 2 3

ON

ON

1 2 3

15

Printed Circuit Board: Adjustments and Connections

Programming the Soft-Modes

The TS Solar/TS Akku is shipped with factory pre-set values for the

Soft-Modes; if the learning cycle is run without any changes to

the factory-settings, then the pre-set values will be programmed

automatically.

The BOTTOM Soft-Stop

The length of the BOTTOM Soft-Stop may be changed during the

first run of the learning-cycle in closing direction.

-

Extending

the BOTTOM Soft-Stop is recommended, if the

garage door slams on closing.

-

Reducing or disabling

the BOTTOM Soft-Stop is recommen-

ded, when the bottom of the garage door does not close comple-

tely. Expecially when mechanical spring-locks are installed, these

might not engage. When the BOTTOM Soft-Stop is disabled, the

garage door reaches the closing position with a higher speed. This

gives the door a higher momentum and the bottom can fall into

the doors‘ frame - the locks can then engage.

Programming the BOTTOM Soft-Mode

The length of the soft-stop can be adjusted during the first au-

tomatic measurement-run in closing direction. Please proceed as

described below:

1. Start the learning cycle (refer to page 11)

. the operator runs in closing direction with low speed

3. press the LERN/LEARN button and keep it pressed - the operator

is now increasing the speed

4. release the LERN/LEARN button at the position where the soft-

stop shall begin

(the operator will safe this position as the

beginning of the BOTTOM soft-stop)

If the Soft-Stop is to be disabled, then the LEARN button must be

pressed until the door is completely closed.

5. the operator will reduce speed with a short delay and then

reach the closing position

6. the operator will procede with the remaining measurement-

runs

When the operators‘ light stops blinking, all measured values

are saved in the memory - the BOTTOM soft-stop now is in the

programmed position.

Disabling the TOP Soft-Modes

The TS Solar/TS Akku will start the closing procedure from

OPENING position with slow speed (e.g. TOP Soft-Mode).

Dependant on the performance of the garage door it might be

necessary to disable this Soft-Mode, especially when the operator

reverses during that period (e.g. pressure detection).

Procedure for disabling the TOP Soft-Mode

Set DIP-Switch no. 1 to OFF before starting the learning cycle

and leave it in that setting until the learning cycles are completed

- the TOP Soft-Mode then is disabled.

After the learning cycles the DIP-switch no. 1 fulfills its‘ normal

function („Normal Force/Higher Force during CLOSING Soft-Stop“

as to page 17).

TIP: should you decide to remove the jumper, then plug it

back onto one pin only - so it remains available on the P.C.B.

for later use.

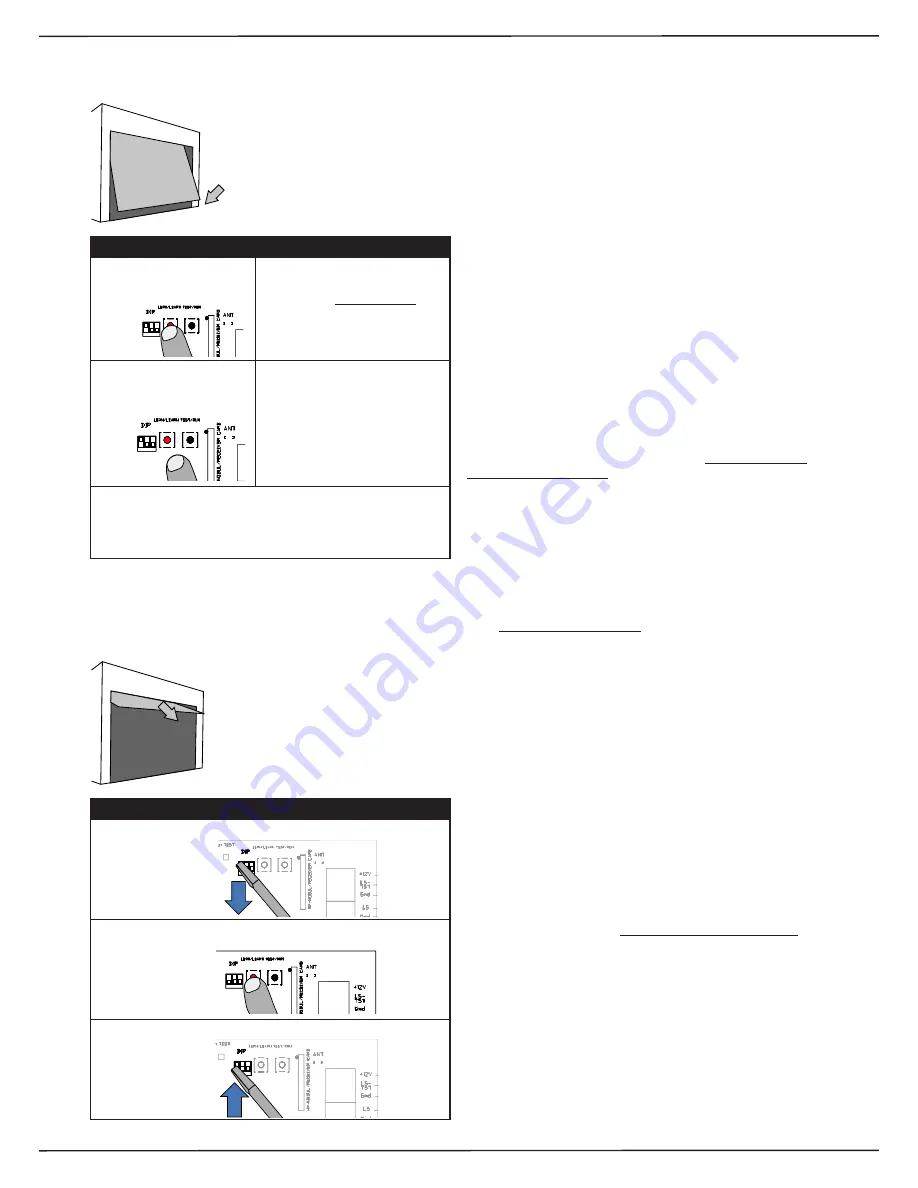

Quick Reference „Programming the BOTTOM Soft-Mode“

1.) During the first learning

cycle in CLOSING direction

Keep the LEARN button pressed

during the first run in CLOSING

direction and keep it pressed -the

operator increases speed

.) The operator is running

in CLOSING direction with

increased speed

Release the LEARN button at the

position where the soft-stop shall

start in future.

If the LEARN button is kept

pressed until the door is

completely shut, then the

soft-stop will be disabled.

3.) The operator reaches the CLOSED position. It will proceed

with the learning-cycle (two more runs) before finishing the pro-

gramming. The CLOSING Soft-Stop will then be set as to your

adjustments.

Quick Reference „Disabling the TOP Soft-Mode“

1.) Set DIP-Switch No. 1 to OFF before starting the learning

cycle

.) Start the learning cycle

3.) Set DIP-Switch No. 1 back to ON when the learning cycle is

completed

TOP soft-mode

BOTTOM soft-mode

Special Functions

Summary of Contents for TS Akku II

Page 24: ...24...