Section 04

ENGINE

Sub-Section 04

(BOTTOM END)

04-04-4

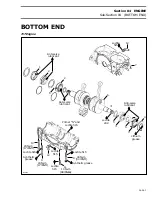

1. TDC gauge

2. Degree wheel

3. Hand tighten nut

4. Needle pointer

– Remove TDC gauge and install on

PTO side

.

– Bring

PTO

piston at Top Dead Center.

Interval between cylinders must be exactly 180°

therefore, needle pointer must indicate 180° on

degree wheel (360° - 180° = 180°).

Any other reading indicates a misaligned crank-

shaft.

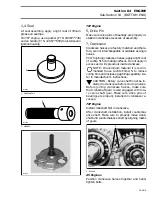

Crankshaft Alignment at Connecting

Rod Journal

Such misalignment may cause a crankshaft hard

to be manually turned. Verification can be done by

measuring deflection each end of crankshaft. Re-

fer to INSPECTION paragraph.

If deflection is found greater than specified toler-

ance, this indicates worn bearing(s), bent and / or

disaligned crankshaft.

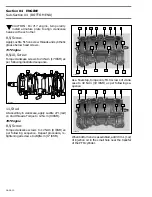

GENERAL

Engine has to be removed from boat to open bot-

tom end.

If crankshaft end seal(s) has / have to be replaced,

bottom end must be opened except for

MAG

side

seal on

787 engine

.

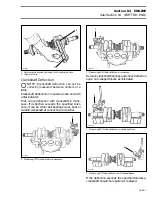

DISASSEMBLY

Remove the following partsþ:

– Ignition housing and PTO flywheel on opposite

side.

1. Separating ignition housing / armature plate from crankcase

– Rotary valve cover and valve.

– Engine support.

– Crankcase retaining screws.

Insert screwdrivers between crankcase lugs and

pry to separate halves being careful not to dam-

age precision machined surfaces.

1. Separate halves by prying at provided lugs

1

F01D4IA

3

2

4

F01D4JA

1

F01D1KA

1

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......