Section 09

PROPULSION AND DRIVE SYSTEMS

Sub-Section 01

(PROPULSION AND DRIVE SYSTEMS)

09-01-12

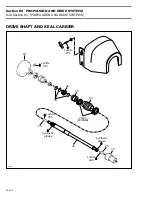

24,25,34, Drive Shaft, Carbon Ring and

Damper

Wear

Visually inspect shape of dampers for deforma-

tion or other damage. Ensure they are firmly re-

tained.

Inspect carbon ring and its contact surface. Check

for scoring, pitting, chipping or other evidence of

wear.

With a finger nail, feel contact surfaces of bearing

and seals. If any irregular surface is found, renew

drive shaft.

1. Carbon ring contact surface

2. Splines condition

3. Seal contact surface

Deflection

Excessive deflection could cause vibration and

damage to drive shaft splines, impeller, flywheel

or seal carrier.

Install drive shaft in V-blocks and set a dial gauge

in center of shaft. Slowly rotate shaft

; difference

between highest and lowest dial gauge reading is

deflection. Refer to the following illustration.

Maximum permissible deflection is 0.5 mm (.020

in).

MEASURING DRIVE SHAFT DEFLECTION

1. Dial gauge

2. V-blocks

19, Impeller

Identification

To identify the impellers refer to the following il-

lustration and chart.

1. Stamped part number

F01J14A

3

1

2

BOAT

MODEL

IMPELLER

P / N

MATERIAL

PITCH

SPORTSTER

271 000 470

Stainless

steel

Progressive

pitch

11° - 25°

CHALLENGER

271 000 620

Stainless

steel

Progressive

pitch

11° - 25°

SPEEDSTER

_

Stainless

steel

Progressive

pitch

_

F01J15A

1

2

F01J4LA

XXXXXXXXX

1

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......