Section 02

MAINTENANCE

Sub-Section 02

(FLUSHING AND CARE)

02-02-3

CARE

1. Check joints for leaks to avoid water accumula-

tion in the bilge.

2. Do not modify hose or socket size as coolant

flow could be altered.

3. When engine is running, water must flow from

bleed outlet(s) indicating that water circulates.

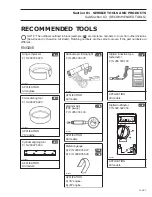

4. For hose clamp installation, use special pliers (P

/ N 295 000 070).

5. When installing hoses onto fittings or when

troubleshooting for water intake in the bilge ar-

ea, confirm that all hoses are properly secured

to the fittings.

6. Check monitoring beeper operation by jumping

terminal of thermosensor wire to ground.

Beeper must operate.

At every verification of monitoring beeper always

apply dielectric grease on thermosensor connec-

tor.

Verify wire terminal on connector for tightness. If

too loose, squeeze terminal slightly at installation.

CAUTION : When investigating for no wa-

ter flow in the cooling system, check all

elbows and straight fittings as well as all hoses

for blockage.

-

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......