Section 08

ELECTRICAL

Sub-Section 03

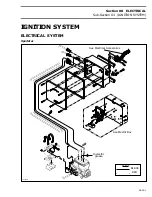

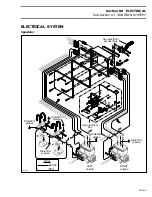

(IGNITION SYSTEM)

08-03-12

IGNITION SYSTEM TESTING PROCEDURE, 787 ENGINE

General

NOTE :

On occasion a component will stati-

cally check good but in fact be defective. In

this instance, removing the original part and re-

placing it with a known good part is the most ac-

curate procedure.

The MPEM (Multi-Purpose Electronic Module) is

part of the ignition system as well as part of elec-

trical system. This section gives testing proce-

dure for ignition-related problems. For other type

of problems, refer to MPEM section.

CAUTION : Whenever replacing a compo-

nent in ignition system, check ignition

timing.

Spark occurrence can be checked with a tester

from Superex Canada Ltd P

/

N 15-785.

To perform verifications, a good quality multime-

ter such as Fluke 73 (P

/

N 529 022 000) can be

used.

When dealing with ignition problems, the follow-

ing items should be checked in this order

:

1. Spark occurrence

/

spark plug condition.

2. Battery condition.

3. MPEM supply fuse condition.

4. Electrical connections.

5. Engine stop

/

safety lanyard

6. MPEM

7. DC-CDI module

8. Magneto output.

9. Ignition coil output.

The first 5 items can be checked with common

automotive equipment. For item 6, refer to

MPEM section. For items 7,8 and 9, refer to the

following procedures.

MPEM (Multi-Purpose Electronic

Module)

ENGINE RPM LIMITER

A defective RPM limiter may cause the following

problems

:

• No spark.

• Misfiring

/

black fouled spark plugs.

• Uninterrupted spark when engine stop

/

safety

• lanyard

/

ignition switch is used.

• Incorrectly controlled engine maximum RPM.

To diagnose spark problems that might come

from the MPEM, first check that its BLACK wire

is perfectly grounded, then if there is no spark,

temporarily bypass the RPM limiter by discon-

necting the BLACK

/

RED

/GREEN wire coming

from engine magneto system. If everything now

works normally, the RPM limiter is defective and

the MPEM must be replaced.

If engine does not stop when using stop

/

safety

lanyard

/

ignition switch, ensure that BLACK

/

RED

/GREEN wire is well connected to MPEM, check

operation of all switches and if everything test

good, the MPEM is defective and must be re-

placed.

To check engine RPM limitation function, run en-

gine with shifter in forward or reverse position

and check its maximum speed. It should be

around 7200

RPM. Otherwise, the RPM limiter is defective and

the MPEM must be replaced.

If the engine maximum speed does not go over

3500 RPM, the problem might come from the

neutral switch. Refer to MPEM section.

Trigger Coil

STATIC TEST : CONTINUITY

1. Disconnect the stator

/

trigger coil plug at the

engine magneto cover. Connect the 6-pin mag-

neto test harness (P / N 295 000 136) at the

engine. DO NOT connect the other end at the

boat’s harness.

2. Connect the multimeter leads as shown (BK

/

YL to one meter lead, YL

/

WH to the other

lead). Resistance should be approximately 242

ohms (

±

10%).

'

-

Summary of Contents for Challenger 5896

Page 1: ......

Page 2: ......

Page 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

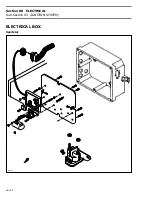

Page 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Page 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Page 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Page 274: ......