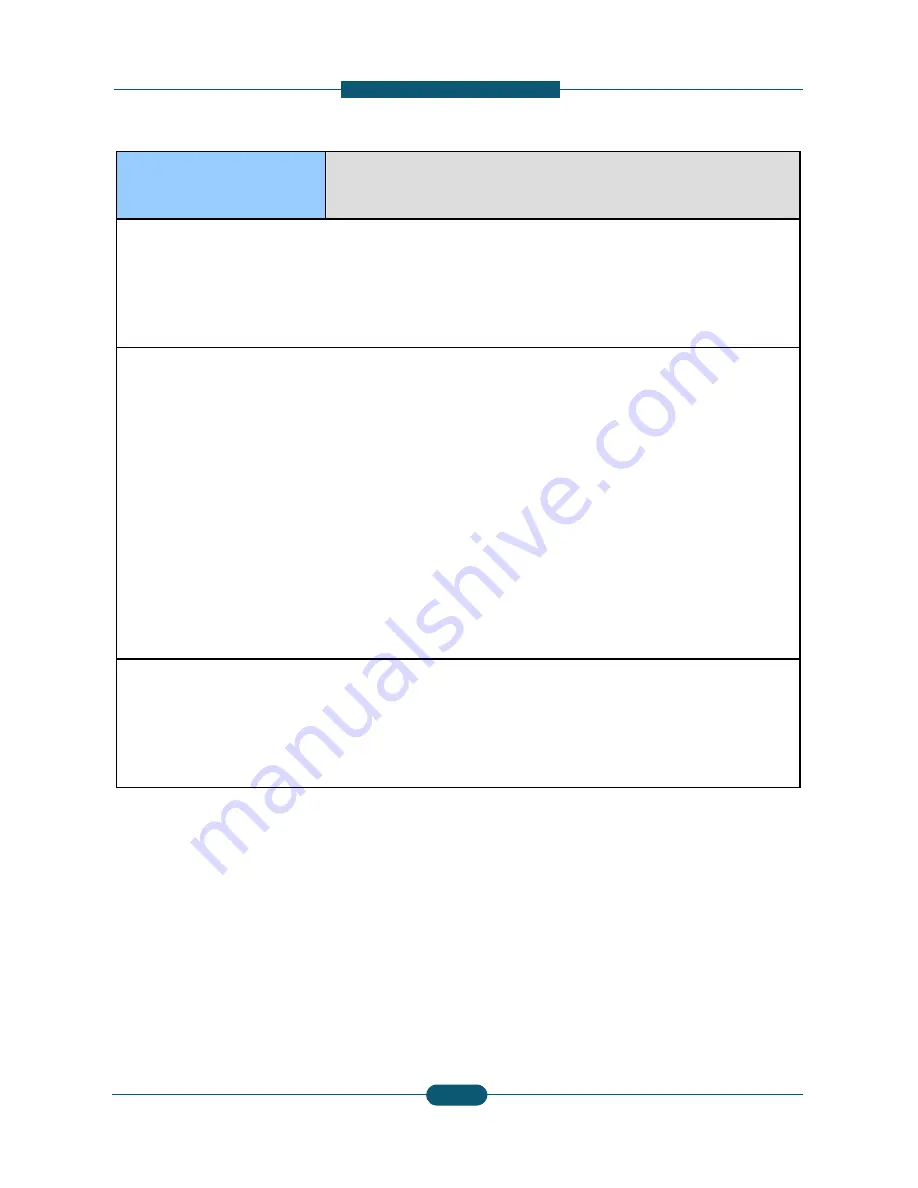

7. Troubles

●

Code :

S1-1213

S1-1214

●

Error message :

Video System Failur

Video System Failur

●

Symptom / Cause :

The error has occurred when you use Security device

TPM chip operation error has occurred.

●

Troubleshooting method :

1. Did you replace the HDD/Video board?

Yes : Update the firmware for the new board.

(Refer to chapter5. Firmware update)

2. Does the problem occur after updating the firmware

Yes :

A. Print the configuration report and check the fir

A. Print the configuration report and check the fir

B. If all software versions are not normal, update

C. If the problem persists, replace the defective d

3. If the problem persists, replace the Video board.

●

Replacement part

- JC59-00031A : HDD

- JC92-02150A : PBA-MAIN (CLX-9350ND)

- JC92-02235A : PBA-MAIN (CLX-9250ND)

Service Manual

CLX-9250/9350 series

7-9

shooting

:

re #S1-1213 : Turn off then on.

re #S1-1214 : Turn off then on.

.

e?

rmware version.

rmware version.

e the firmware again.

device. (HDD / Video board )

SAMSUNG ELECTRONICS

93