Section 03 787 RFI ENGINE

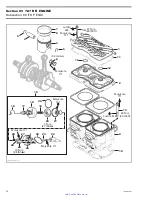

Subsection 03 (TOP END)

MAINTENANCE

There are no wear parts anywhere in the system

and there are no adjustments to be periodical-

ly checked. The only possible maintenance re-

quired would be cleaning of carbon deposits from

the guillotine slide. Cleaning intervals would de-

pend upon the user's riding style and the quality

of the oil used. We suggest annual cleaning of

the valve. If a customer uses a lower than recom-

mended quality oil, more frequent cleaning may

be required.

No special solvents or cleaners are required when

cleaning the valve.

BORING PRECAUTION

In its stock configuration the RAVE valve guillo-

tine has a minimum of 0.5 mm (.020 in) clearance

to the cylinder bore measured at the center line

of the cylinder. This is the minimum production

clearance.

There is only a first oversize piston available for the

787 RFI engine. That piston is 0.25 mm (.010 in)

larger in diameter than the stock piston. When

the oversize is installed, the guillotine will have

a minimum clearance of 0.375 mm (.015 in) with

the cylinder bore. This is the minimum operat-

ing clearance the guillotine should be used with.

Clearance less than 0.375 mm (.015 in) will require

reworking of the guillotine to achieve the proper

clearance and radius.

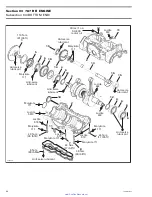

DISASSEMBLY

RAVE Valve

Loosen Allen screws

no. 26

each side of RAVE

valve.

F06D0QA

1

1. Remove screws

Remove RAVE valve

no. 15

.

Remove the cover

no. 18

of the valve by releasing

the spring

no. 16

.

WARNING

Firmly hold cover to valve base. The com-

pression spring inside the valve is applying

pressure against the cover.

F06D0RA

1

1. Spring

Remove the compression spring

no. 19

.

74

smr2005-082

www.SeaDooManuals.net