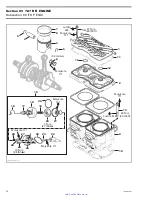

Section 03 787 RFI ENGINE

Subsection 03 (TOP END)

F01D8LA

Cylinder Base Gasket

NOTE:

The general procedure is to install a new

gasket of the same thickness. However, if you do

not know the gasket thickness that was installed

or if a crank repair has involved replacement of

connecting rods, refer to COMBUSTION CHAM-

BER VOLUME MEASUREMENT in ENGINE MEA-

SUREMENT section to properly determine the re-

quired gasket thickness.

Different thicknesses of cylinder base gaskets are

used for a precise adjustment of the combustion

chamber volume.

To identify gasket thickness, refer to the identifi-

cation holes on the gasket.

F01D67A

1

TYPICAL

1. Identification holes

GASKET THICKNESS

IDENTIFICATION

HOLES

0.3 mm (.012 in)

3

0.4 mm (.016 in)

4

0.5 mm (.020 in)

5

0.6 mm (.024 in)

6

0.8 mm (.031 in)

8

Piston

At assembly, place the pistons

no. 3

with the let-

ters

″

AUS

″

(over an arrow on the piston dome) fac-

ing in direction of the exhaust port.

A01C01A

AUS

1

1. Exhaust side

NOTE:

The exhaust ports are located on the same

side as the intake.

Carefully cover crankcase opening as for disas-

sembly.

Piston Pin and Roller Bearing

To install roller bearing

no. 4

and piston pin

no. 6

use the piston pin puller (P/N 529 035 503) with

the set of sleeves (P/N 529 035 542).

– Replacement bearings are held in place by a lo-

cating sleeve outside and 2 plastic cage halves

inside.

– Push needle bearing together with inner halves

out of the locating sleeve into the connecting

rod bore.

– Replace the inner halves by the appropriate

sleeve tool in the connecting rod bore.

– Insert piston pin into piston until it comes flush

with inward edge of piston hub.

– Warm piston to approximately 50 - 60°C (122 -

140°F) and install it over connecting rod.

smr2005-082

81

www.SeaDooManuals.net