Section 02 717 ENGINE

Subsection 04 (BOTTOM END)

Touch the inner race of the bearing with the tem-

perature indicator stick (P/N 529 035 970). Stick

will liquefy when the bearing reach the proper

temperature.

A32CB9A

TYPICAL

WARNING

Do not touch heated bearing with bare han-

dle. Wear heat resisting gloves before han-

dling the heated bearing(s).

Smear Loctite 767 (antiseize lubricant) (P/N 293

800 070) on part of crankshaft where bearing fits.

A32CB6A

TYPICAL

Install the distance ring

no. 12

. Make sure to posi-

tion it with its chamfer toward the counterweight

of the crankshaft.

Slide in the inner bearing. Push bearing to end

position.

Install the retaining disk.

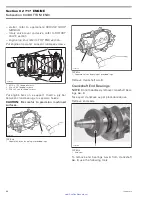

To properly position the outer bearing(s), the dis-

tance gauge (P/N 529 034 800) must be temporar-

ily installed against the inner bearing. Slide the

outer bearing until stopped by the distance gauge,

then remove the distance gauge.

F01B0HA

1

1. Distance gauge

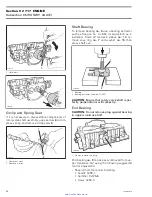

F01D1YA

1

2

TYPICAL

1. Distance gauge

2. Outer bearing

Crankcase

NOTE:

Rotary valve shaft must be installed in

crankcase before closing halves.

CAUTION:

Before joining crankcase halves,

make sure that crankshaft gear is well engaged

with rotary valve shaft gear.

Crankcase Sealant Application

IMPORTANT:

When beginning the application of

the crankcase sealant, the assembly and the first

torquing should be done within 10 minutes. It is

suggested to have all you need on hand to save

time.

44

smr2005-078

www.SeaDooManuals.net