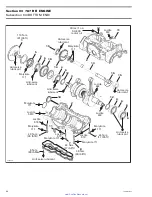

Section 03 787 RFI ENGINE

Subsection 04 (BOTTOM END)

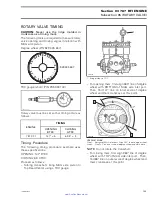

F00D0UA

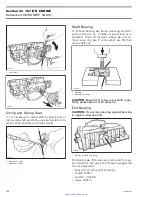

1

1. Gear notch aligned with the crankcase

– The notch of the couterweight on the opposite

end of the counterbalance shaft must also be

aligned with the cranckcase.

F00D0VA

1

1. Counterweight notch aligned with the crankcase

If notches are not aligned with the crankcase, re-

move the gear and repeat the procedure until the

notches are properly aligned.

Crankcase

NOTE:

Rotary valve shaft must be installed in

crankcase before closing halves.

CAUTION:

Before joining crankcase halves,

make sure that crankshaft gear is well engaged

with rotary valve shaft gear.

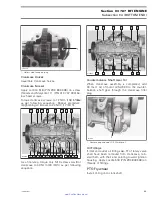

Crankcase Sealant Application

IMPORTANT:

When beginning the application of

the crankcase sealant, the assembly and the first

torquing should be done within 10 minutes. It is

suggested to have all you need on hand to save

time.

NOTE:

It is recommended to apply this specific

sealant as described here to get an uniform appli-

cation without lumps. If you do not use the roller

method, you may use your finger to uniformly dis-

tribute the sealant.

Use the silicone-based Loctite 5910 (P/N 293 800

081) on mating surfaces.

NOTE:

Refer to the product label for the curing

time.

CAUTION:

Do not use other products to seal

crankcase. Do not use an activator with the

Loctite 5910.

Using a non silicone-based

sealant over a previously sealed crankcase

with Loctite 5910 will lead to poor adhesion

and possibly a leaking crankcase. Even after

cleaning, the Loctite 5910 would leave incom-

patible microscopic particles.

Use a plexiglass plate and apply some sealant on

it. Use a soft rubber roller (50 - 75 mm (2 - 3 in))

(available in arts products suppliers for printmak-

ing) and roll the sealant to get a thin uniform coat

on the plate (spread as necessary). When ready,

apply the sealant on crankcase mating surfaces.

F12R17A

smr2005-083

97

www.SeaDooManuals.net