Section 02 717 ENGINE

Subsection 04 (BOTTOM END)

NOTE:

It is recommended to apply this specific

sealant as described here to get an uniform appli-

cation without lumps. If you do not use the roller

method, you may use your finger to uniformly dis-

tribute the sealant.

Use the Loctite 5910 (P/N 293 800 081) on mating

surfaces.

CAUTION:

Do not use other products to seal

crankcase. Do not use an activator with the

Loctite 5910. Using other products or non sil-

icone-based sealant over a previously sealed

crankcase with Loctite 5910 will lead to poor

adhesion and possibly a leaking crankcase.

Even after cleaning, the Loctite 5910 would

leave incompatible microscopic particles.

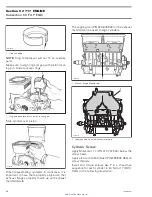

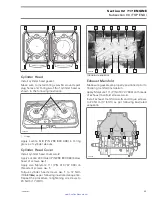

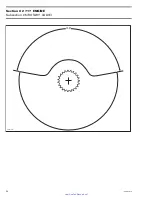

Use a plexiglass plate and apply some sealant on

it. Use a soft rubber roller (50 - 75 mm (2 - 3 in))

(available in arts products suppliers) and roll the

sealant to get a thin uniform coat on the plate

(spread as necessary). When ready, apply the

sealant on crankcase mating surfaces.

F12R17A

F12R18A

TYPICAL

Do not apply in excess as it will spread out inside

crankcase.

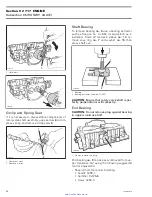

Crankshaft Seals

When installing seals

no. 5

, apply a light coat of

Molykote 111 (P/N 413 707 000) on seal lips.

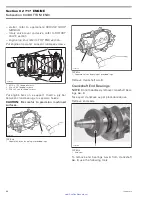

Crankshaft

When installing crankshaft in crankcase, make

sure drive pins

no. 6

of bearings are properly

installed in crankcase recesses.

F00D0OA

1

1. Drive pins

Crankcase Halves

Assemble crankcase halves.

NOTE:

Temporarily install armature plate to align

crankcase halves with each other.

smr2005-078

45

www.SeaDooManuals.net