Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

F01D5VA

1

1. Combustion chamber

NOTE:

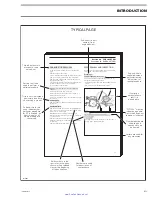

When checking the combustion chamber

volume, engine must be cold, piston must be free

of carbon deposit and cylinder head must be lev-

eled.

– Remove both spark plugs and bring one piston

to Top Dead Center using a TDC gauge.

– Obtain a graduated burette (capacity 0 - 50 cc)

and fill with an equal part (50/50) of gasoline and

injection oil.

F00B0BA

1

1. Graduated burette (0 - 50 cc)

– Open burette valve to fill its tip. Add liquid in

burette until level reaches 0 cc.

– Inject the burette content through one spark

plug hole until liquid touches the top hole.

F00D0HA

1

TYPICAL

1. Top of spark plug hole

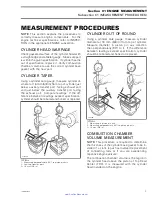

NOTE:

The liquid level in cylinder must not drop

for a few seconds after filling. If so, there is a

leak between piston and cylinder. The recorded

volume would be false.

– Let burette stand upward for about 10 minutes,

until liquid level is stabilized.

– Read the burette scale to obtain the quantity of

liquid injected in the combustion chamber.

The volume should be within the allowable range.

Refer to TOP END section of the appropriate en-

gine for the specifications.

If the volume of the combustion chamber is not

within specifications, change cylinder base gasket

thickness as follow.

A higher volume dictates a thinner gasket.

A lower volume dictates a thicker gasket.

– Repeat the procedure for the other cylinder.

PISTON/CYLINDER WALL

CLEARANCE

Method with a Used Piston

Using a micrometer, measure piston skirt perpen-

dicularly (90°) to piston pin and at the specified dis-

tance as per following table.

ENGINE

MAXIMUM “A” mm (in)

717

29 (1.142)

787 RFI

28 (1.102)

2

smr2005-085

www.SeaDooManuals.net