Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

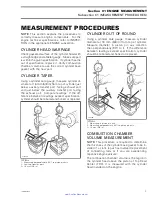

NOTE:

Ring/piston groove clearance can be cor-

rectly measured only on rectangular ring which is

bottom ring.

A35C31A

TYPICAL

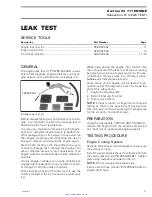

RING END GAP

Position ring halfway between exhaust port and

top of cylinder.

NOTE:

In order to correctly position ring in cylin-

der, use piston as a pusher.

Using a feeler gauge, check ring end gap. If gap

exceeds specified tolerance, rings should be re-

placed.

F01D0OA

1

2

1. Top of cylinder

2. Ring end gap

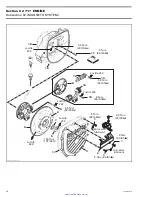

CRANKSHAFT (ASSEMBLED

ENGINE)

The following checks can be performed with en-

gine in watercraft without overhauling engine.

Crankshaft Alignment at Center

Main Journal

Since it is an assembled crankshaft it can become

misaligned or deflected. Crankshaft can be twist-

ed on center main journal, changing timing of one

cylinder in relation with the other.

F01D1NA

1

1. Main journal alignment here

To accurately check if crankshaft is twisted on cen-

ter main journal, proceed as follows:

– Remove magneto housing cover.

– Remove flywheel nut and magneto roto. Refer

to MAGNETO SYSTEM for procedures.

– Install the degree wheel (P/N 529 035 607) on

crankshaft end. Hand-tighten nut only.

– Remove both spark plugs.

– Install a TDC gauge in spark plug hole on MAG

side.

– Bring MAG piston at Top Dead Center.

– As a needle pointer, secure a wire with a cover

screw and a washer.

– Rotate degree wheel (NOT crankshaft) so that

needle pointer reads 360°.

smr2005-085

5

www.SeaDooManuals.net