Section 01 ENGINE MEASUREMENT

Subsection 01 (MEASUREMENT PROCEDURES)

F01D1WA

1

2

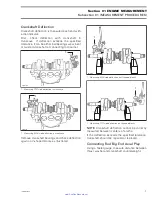

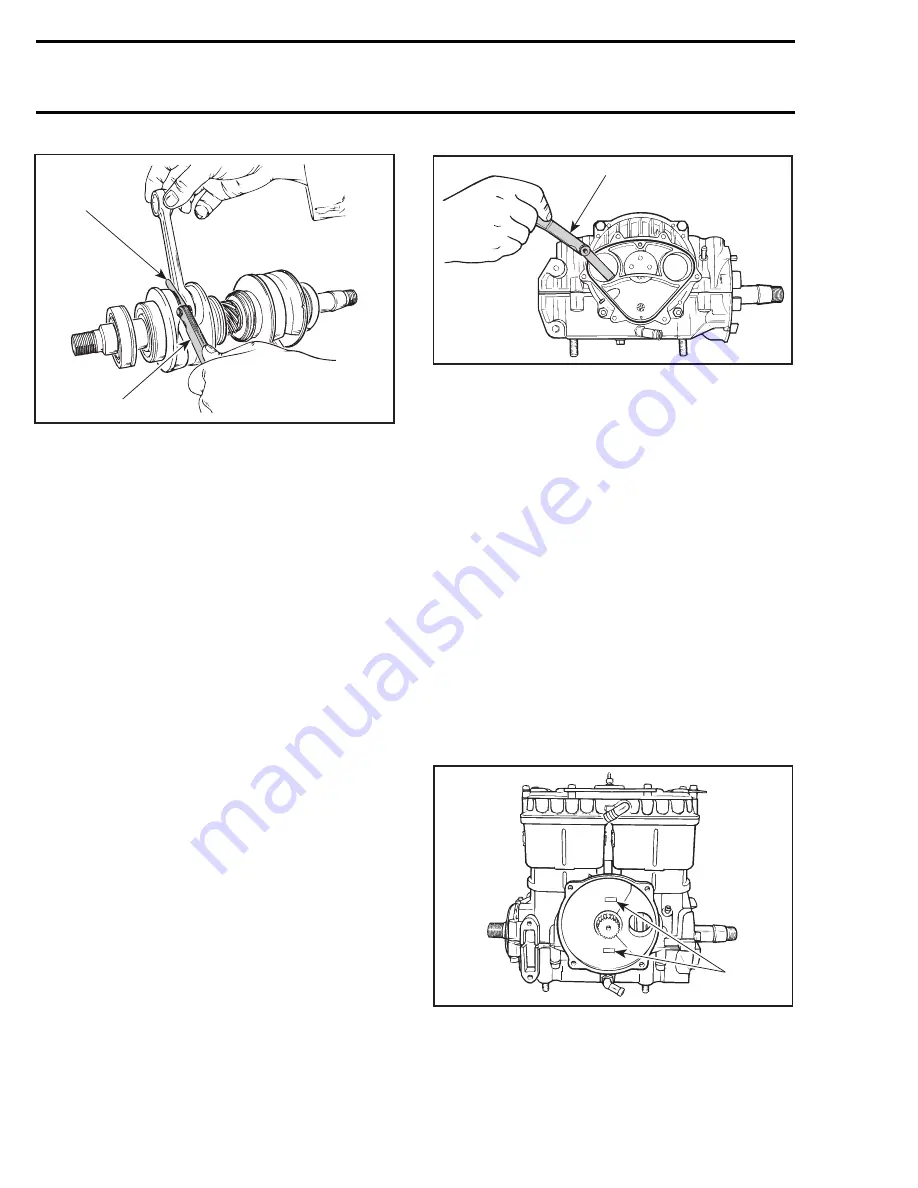

1. Measuring big end axial play

2. Feeler gauge

Connecting Rod Straightness

Align a steel ruler on edge of small end connecting

rod bore. Check if ruler is perfectly aligned with

edge of big end.

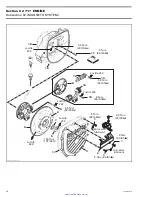

ROTARY VALVE

Rotary Valve/Cover Clearance

45° FEELER GAUGE METHOD

Remove intake manifold from rotary valve cover.

Remove rotary valve cover and valve.

Remove O-ring from rotary valve cover.

Reinstall cover WITHOUT its O-ring and torque

screws to 20 N•m (15 lbf•ft).

Insert a feeler gauge blade through cover inlet

ports to verify clearance. At least verify clearance

at two different places in each port.

Feeler gauge blade thickness according to specifi-

cations should fit between rotary valve and cover.

F01D53A

1

1. 45° feeler gauge

If rotary valve cover clearance is out of specifica-

tions, machine rotary valve cover seating surface

or replace the cover.

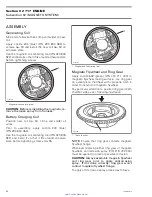

SOLDERING WIRE METHOD

Remove rotary valve cover.

Remove O-ring from rotary valve cover.

Use the following type of solder:

– resin core

– diameter : 0.8 mm (.032 in)

– electronic application (available at electronic

stores).

Install 2 soldering wire pieces of 13 mm (1/2 in)

long directly on rotary valve, one above and one

below rotary valve gear. Apply grease to hold sol-

der in position.

Refer to the following illustration for proper posi-

tion of rotary valve and pieces of soldering wire.

F01D3PA

1

TYPICAL

1. Soldering wires

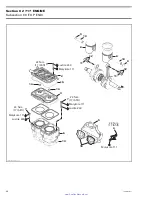

Reinstall cover WITHOUT its O-ring and torque

screws to 20 N•m (15 lbf•ft).

8

smr2005-085

www.SeaDooManuals.net