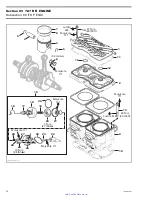

Section 02 717 ENGINE

Subsection 05 (ROTARY VALVE)

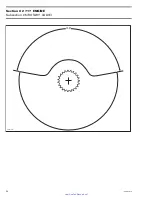

ROTARY VALVE TIMING

CAUTION:

Never use the ridge molded in crank

case as a timing mark.

The degree wheel (P/N 529 035 607) and the TDC

gauge (P/N 295 000 143) are required to measure

rotary valve opening and closing angles in relation

with MAG side piston.

360 350 340

330

320

310

30

0

29

0

28

0

27

0

26

0

25

0

240

230

220

210

200

190

180

170

160

15

0

14

0

13

0

12

0

11

0

10

0

90

80

70

60

50

40

30

20 10

10

20

30

40

50

60

70

80

90

10

0

11

0

12

0

13

0

140

150

160

170

180

19

0

200

210

22

0

23

0

24

0

25

0

26

0

27

0

28

0

29

0

30

0

31

0

32

0

330

340

350 360

F00B0DB

529 035 607

295 000 143

Rotary valve must be set so that timing occurs as

follows:

TIMING

ENGINE

OPENING

BTDC

CLOSING

ATDC

717

147° ± 5

65.5° ± 5

Timing Procedure

The following timing procedure example uses

these specifications:

OPENING: 147° BTDC

CLOSING: 65° ATDC

Proceed as follows:

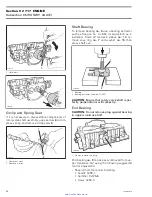

– Turning crankshaft, bring MAG side piston to

Top Dead Center using the TDC gauge.

1

F01D2IA

1. Bring piston to TDC

– For opening mark, first align 360° line of degree

wheel with BOTTOM of MAG side inlet port.

Then, find 147° line on inner scale of degree

wheel and mark crankcase at this point.

F01D3DC

147°

2

1

OPENING MARK

Step 1:

Bottom of MAG inlet port. Align 360° line of degree wheel

Step 2:

Find 147° on inner scale of degree wheel and mark here

NOTE:

Do not rotate the crankshaft.

– For closing mark, first align 360° line of degree

wheel with TOP of MAG side inlet port. Then,

find 65° line on outer scale of degree wheel and

mark crankcase at this point.

smr2005-079

55

www.SeaDooManuals.net