4.

Perform position adjustment of the feed direction (reduce horizontal stripes).

Feed direction means the feed direction of the media. Perform the correction adjusting to the media in advance

because horizontal strips are more likely to occur during printing when the movement distance of the media

changes subtly depending on the media’s thickness.

Procedure

1.

Press [

◀

] to select "SET".

CALIBRATION

[SET] NEXT

2.

Press [ENTER] to confirm your entry.

Printing of the test pattern starts.

You can select "NEXT" and press [ENTER] to skip the current menu and proceed to the next menu.

3.

Press [ENTER].

INPUT

ADJ. VALUES

4.

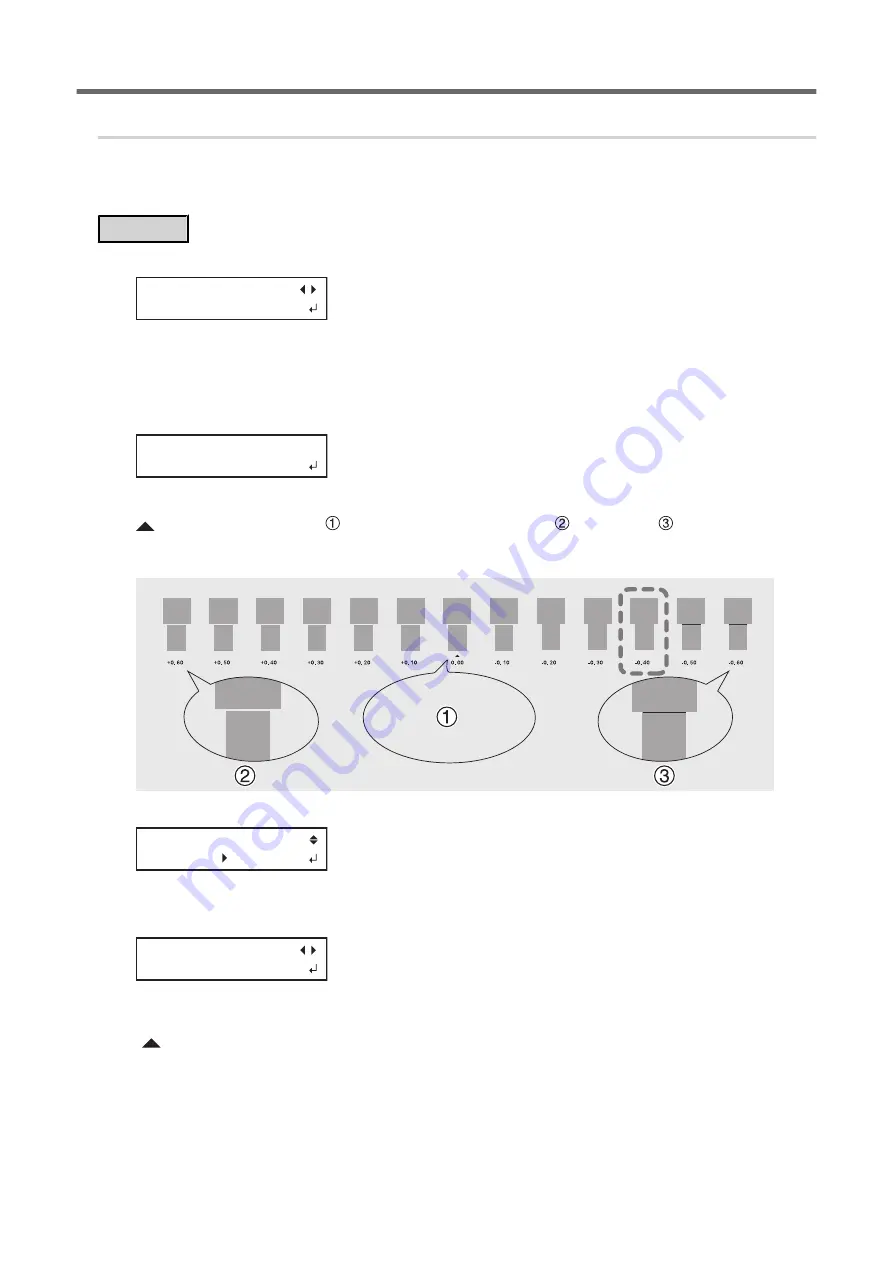

View the printed test pattern, and then determine the correction value.

= Current correction value ( ) Select the value to make the gap ( ) and overlap ( ) between the up-

per/lower squares smallest. In the case of the following figure, select "-0.40." When you cannot choose be-

tween two sequential numbers, specify a value that is between them.

5.

Press [

▲

] or [

▼

] to select the correction value.

CALIBRATION

0.00% +0.05%

6.

Press [ENTER] to confirm your entry.

7.

Press [

◀

] to select "SET".

REDO ADJ.?

[YES] DONE

8.

Press [ENTER] to confirm your entry.

The test pattern is printed again. Check that the gap and overlap are the smallest for the figure indicated by

"

" (that is, the current correction value). If the gap and overlap are smaller for another figure, return to

step 5 to perform the setting again.

If you do not need to change the correction value, press [ENTER] again.

9.

Press [

▶

] to select "DONE".

Printing Output

68

1. Printing Method

Summary of Contents for TrueVIS VG2-540

Page 9: ...Chapter 1 Basic Handling Methods 8 ...

Page 36: ...Setup of Media 2 Basic Operations 35 ...

Page 43: ...Setup of Media 42 2 Basic Operations ...

Page 60: ...Ink Pouch TR2 Cleaning Liquid Pouch Replacement 2 Basic Operations 59 ...

Page 61: ...Chapter 2 Output Method 60 ...

Page 70: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Printing Output 1 Printing Method 69 ...

Page 138: ...Chapter 3 Optimizing Quality and Efficiency 137 ...

Page 195: ...W1100mm B Adjusting the Output start Location 194 2 Optimizing Work Efficiency ...

Page 217: ...Chapter 4 Maintenance 216 ...

Page 272: ...Chapter 5 Troubleshooting Methods 271 ...

Page 305: ...Chapter 6 Appendix 304 ...

Page 308: ...8 Detach the blade holder Preparing to Move the Machine 1 Operations When Moving the Unit 307 ...