9.

Press [

▶

].

10.

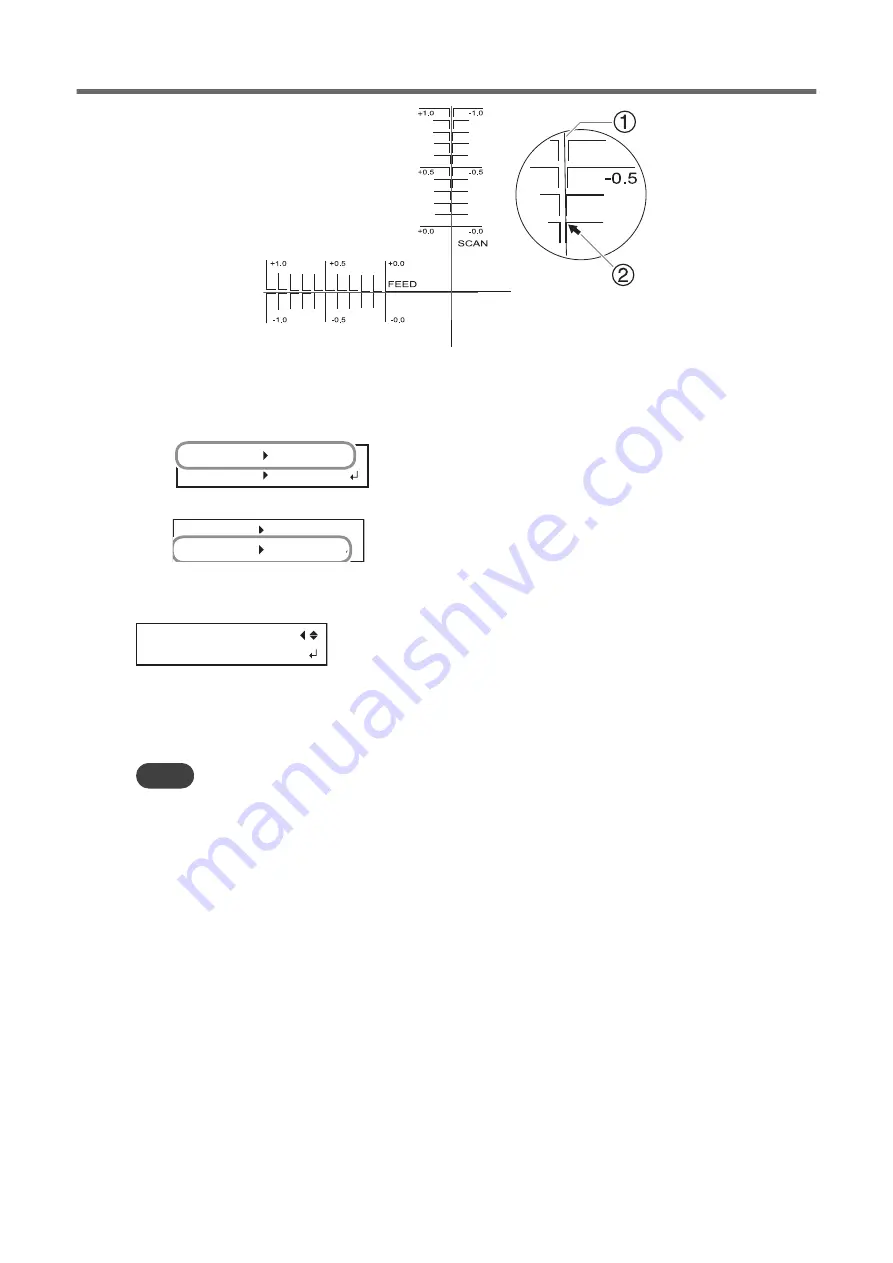

Set the correction values for the feed direction "F" and the scan direction "S."

(1)

Press [

▲

] or [

▼

] to set the correction value for the feed direction (F).

F:+0.30 +0.35mm

S:-0.40 -0.45mm

(2)

Press [

◀

] or [

▶

] to set the correction value for the scan direction (S).

F:+0.30 +0.35mm

S:-0.40 -0.45mm

(3)

When you have finished setting the correction values, press [ENTER].

11.

Press [MENU], then [

▲

] to display the screen shown below.

PRINT-CUT ADJ.

TEST PRINT

12.

Press [ENTER].

The test pattern (P&C1) is printed and cut. If the printing and cutting lines are aligned, adjustment is com-

plete. If further adjustment is needed, press [

▼

], then [

▶

] to go back to step 10 and fine-tune the adjust-

ment.

MEMO

• Default settings

• F (correction value of the media feed direction): 0.00 mm

• S (correction value of the cutting carriage movement direction): 0.00 mm

Accurately Adjusting the Settings for Printing and Cutting

1. Optimizing the Output Quality

171

Summary of Contents for TrueVIS VG2-540

Page 9: ...Chapter 1 Basic Handling Methods 8 ...

Page 36: ...Setup of Media 2 Basic Operations 35 ...

Page 43: ...Setup of Media 42 2 Basic Operations ...

Page 60: ...Ink Pouch TR2 Cleaning Liquid Pouch Replacement 2 Basic Operations 59 ...

Page 61: ...Chapter 2 Output Method 60 ...

Page 70: ...REDO ADJ YES DONE 10 Press ENTER to confirm your entry Printing Output 1 Printing Method 69 ...

Page 138: ...Chapter 3 Optimizing Quality and Efficiency 137 ...

Page 195: ...W1100mm B Adjusting the Output start Location 194 2 Optimizing Work Efficiency ...

Page 217: ...Chapter 4 Maintenance 216 ...

Page 272: ...Chapter 5 Troubleshooting Methods 271 ...

Page 305: ...Chapter 6 Appendix 304 ...

Page 308: ...8 Detach the blade holder Preparing to Move the Machine 1 Operations When Moving the Unit 307 ...