Maintenance

© Panasonic Industrial Devices SUNX Co., Ltd. 2020

123

When using as a safety device for a press machine in Japan

When using as a safety device for a press machine in Japan, press machine work supervisors and

personnel in charge of the matters described in No. 1, No. 2, and No. 4 of Article 134 of the Occupa

-

tional Safety and Health Act are required to perform inspection prior to the start of work and perform

periodic inspection. Press machine work supervisors, etc. must inspect the items below prior to the

start of work and record/retain the results.

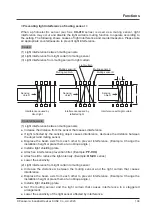

Device emitter

●

Firmness of installation

●

Suitability of installation position (safe distance and vertical position)

●

Existence of damage

●

Existence of external wire abnormalities

●

Existence of dirt on emitter

●

Certainty of detection states

Device receiver

●

Firmness of installation

●

Suitability of installation position (safe distance and vertical position)

●

Existence of damage

●

Existence of external wire abnormalities

●

Existence of dirt on emitter

●

Certainty of detection states

Specified control unit

SF-C11

,

SF-C13

●

External wiring

●

Indicators

●

Abnormal operation of switches, etc.

●

Firmness of installation

For details, refer to “About the Revision of the Safety Device Management Guidelines for Press Ma-

chines” (Ministry of Health, Labour and Welfare Publication 930 No. 11, September 30, 2015).

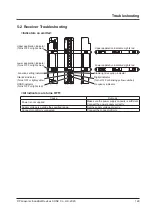

4-2 Periodic Inspection (Every Six Months)

WARNING

Be sure to inspect the following items every six months and verify that there are no abnormalities.

Risk of death or serious injury if inspection is neglected or the device is operated with an abnormal

condition.

Checklist (periodic inspection)

Check column

Inspection item

□

The structure of the machine does not obstruct any safety mechanisms for stopping operation.

□

No modification has been made in the machine control system that obstructs the safety mechanisms.

□

Output from the device is correctly detected.

□

Wiring from the device is correct.

□

The response time of the overall system is equal to or less than the calculated value.

□

The current number of operation cycles (time) of parts with a limited service life is less than the

number of service life cycles (time).

□

No screws or connectors related to the device are loose.

□

No objects that scatter or reflect light have been added near the device.

Summary of Contents for SF4D-*-01 Series

Page 2: ... Panasonic Industrial Devices SUNX Co Ltd 2020 2 MEMO ...

Page 6: ... Panasonic Industrial Devices SUNX Co Ltd 2020 6 MEMO ...

Page 120: ...Functions Panasonic Industrial Devices SUNX Co Ltd 2020 120 MEMO ...

Page 134: ...Troubleshooting Panasonic Industrial Devices SUNX Co Ltd 2020 134 MEMO ...

Page 168: ... Panasonic Industrial Devices SUNX Co Ltd 2020 168 MEMO ...