160

5.1.9.

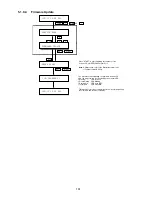

Service Mode 9 (System Maintenance)

5.1.9.1.

Overview

This Service Mode is used to maintain and/or update the firmware of the machine. Use the following

procedure for System Maintenance.

System Maintenance Table

Service Mode 9

Step

Operation or Unit Condition

LCD Display

1

Standby

2

Press “FUNCTION” and then “7”.

3

Press “MONITOR” four times, then press “*”.

4

Press “9”.

Use “V” or “/\“ to scroll to the desired maintenance task.

5

Press “SET” and “START” .

6

After completed, the machine returns to Standby.

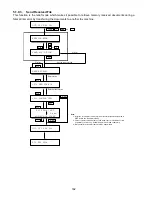

No.

Maintenance Mode

Description

1

FIRMWARE UPDATE

Updates the firmware in the machine with the Master Firmware

from the PC.

After the firmware is updated, the machine reboots

automatically and returns to standby.

2

SEND RECEIVED FILE Transfers documents from memory to another fax machine

during a fatal printer error.

OCT-12 10:58 00%

SET MODE (1-8)

SERVICE MODE

FIRMWARE UPDATE

* IN PROGRESS *

OCT-12 10:58 00%

Summary of Contents for Panafax UF-490

Page 2: ...2 ...

Page 15: ...15 1 4 Control Panel For USA and Canada For Other Countries ...

Page 37: ...37 24 Remove the Pressure Roller 322 25 Remove the Exit Roller 304 24 25 ...

Page 63: ...63 3 10 ILS PC Board CN73 Refer to SC PC Board CN11 ...

Page 65: ...65 3 12 ACI PC Board Refer to Power Supply Unit CN101 ...