No. SX-DSV02310 - 119 -

R2.0 Motor

Business

Division,

Appliances Company, Panasonic Corporation

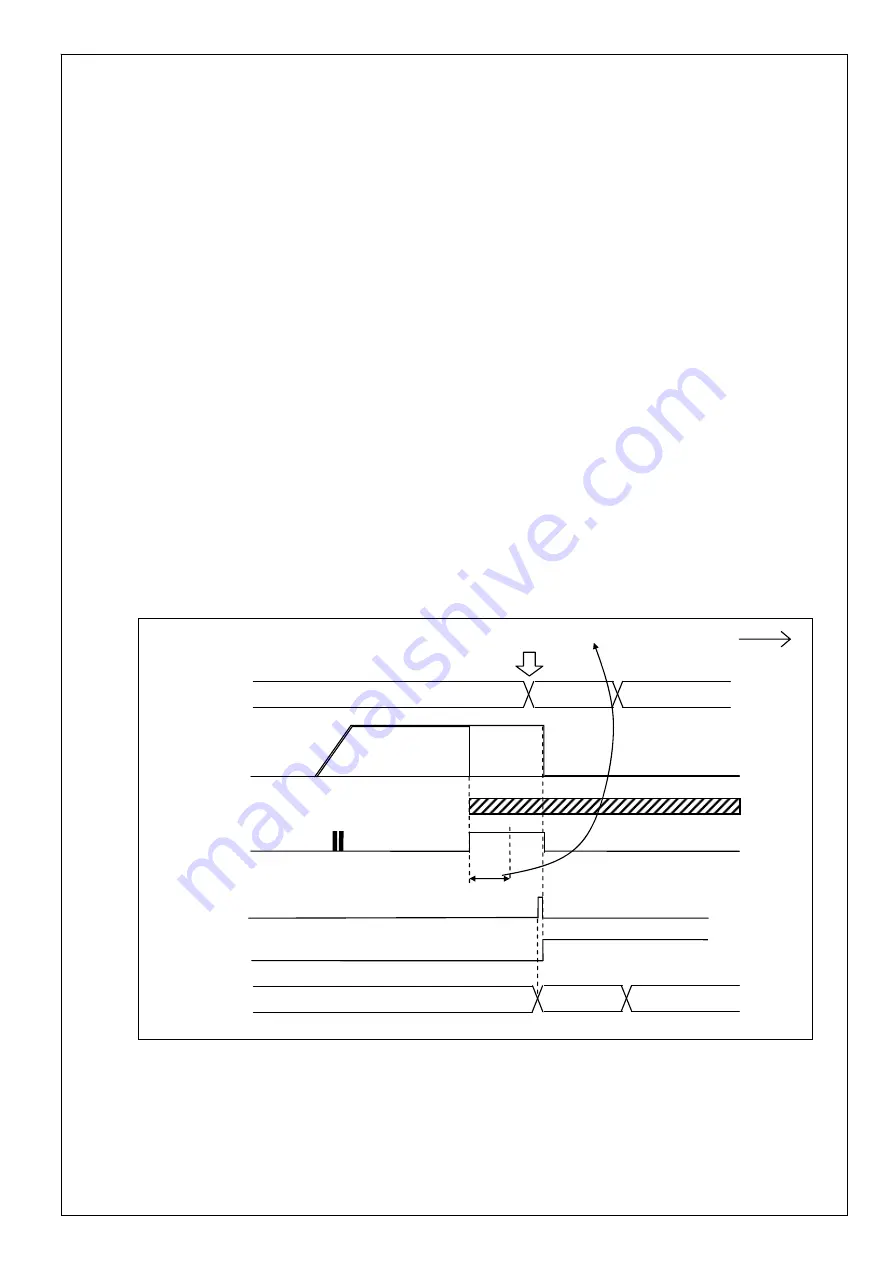

7-2-3-4 Example of cyclic homing operation 4

Below shows an example of return-to-home operation in the cyclic position control (CP) mode using the mechanical

stopper.

1) Lower the thrust limit value with using parameter command (26h) or TL SW bit of command.

Note: For setting the thrust limit value, see section 4-5-3.

2) Execute the positioning according to command position, which is based on the position at power-up. At this time,

lower Command Velocity for safety.

3) Actual velocity will be 0 when the slider hit the stopper, and the status will show the thrust limited (thrust limited

bit will be 1).

4) After verifying that the thrust limited status continued for specified period (t1), switch the command from

normal (20h) to return-to-home command (24h). Set Type_Code to actual position set (021h) and setting position

(Byte 12–15) to 0 (or desired value). Do not change the command position.

5) When the process of actual position set has completed in the servo driver, the driver will ignore the value of

command position and stop the motor (servo-lock) at the setup position. Then it will set homing complete bit to 1.

Note that during feedforward the value remains valid. If this causes a problem, keep feedforward value at 0

during homing process.

6) After confirming that homing complete bit has become 1, then set the command position to the set actual

position.

7) Change the command code back to normal command (20h).

Then, positioning will start according to the new reference. Therefore, be sure to perform step 6) before changing

the command code back to the normal command.

8) Bring the thrust limit value to the previous value.

*1) Command velocity is the differences of command position for the command update cycle. (It is internal

operation value of the servo driver.)

*2) Thrust limited bit may be 1 even if the slider does not hit the stopper since the thrust limit is lowered. Therefore,

adjust t1 to avoid mis-detecting.

Note that position deviation error (Err. 24.0) might occur when t1 is too large.

Command code

Actual velocity

Actual position set

Command

velocity

Torque_Limited

20h 20h

24h

*1)

*2)

Velocity

Time

t1

Homing_Complete

Busy

20h 20h

24h

Mechanical stopper

Command

code

echo