194

Cha

p

ter 7

Calculation

, Anal

ysis

, a

nd Out

p

ut o

f Ins

p

ection Result

s

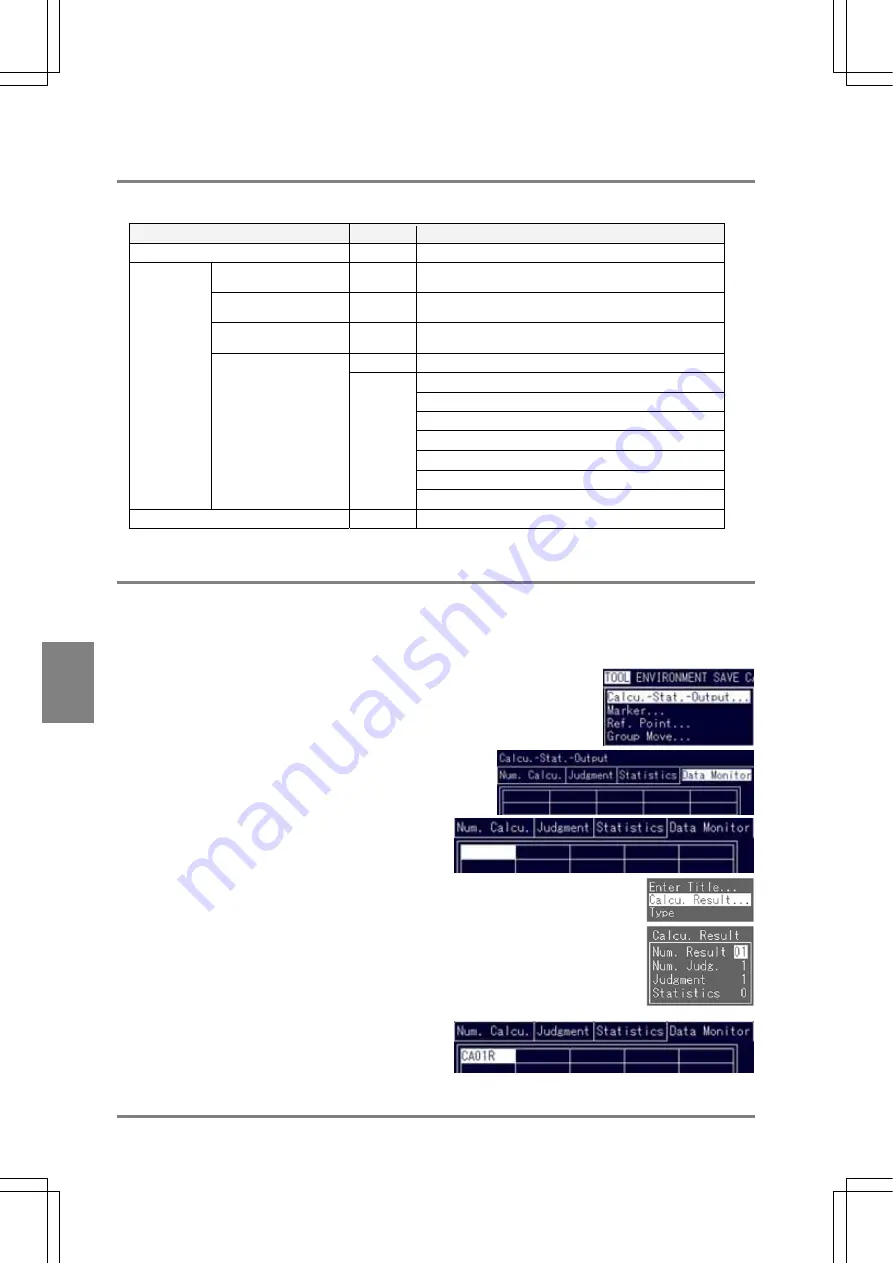

7.5.2 Data Can Be Displayed in the Data Monitor Table

The data listed below can be referred to the Data Monitor.

Reference Data

No.

Content

Title -

Titles

containing

numbers, alphabets and symbols

Result of Numeric

Calculation

01 to 96

Calculation result of a Numeric Calculation formula

Judgment of Numeric

Calculation

01 to 96

Judgment result of a Numeric Calculation formula

Judgment of Judgment

Calculation

01 to 96

Judgment result

00 Scan

Number

OK Count

NG Count

OK Average

OK Disperse

Max.

Min.

Calculation

Result

Statistics

01 to 96

Range

Product Type

-

The number of current product type

7.5.3 Data

Displaying

Result of Numeric Calculation and Judgment of Numeric/Judgment Calculation

To refer the result and judgment of numeric calculation and judgment of judgment calculation, follow the steps

below.

1. Select "TOOL” > "Calcu. -Stat.-Output" from the menu bar.

The subwindow for calculation, statistics and output setting is

displayed.

2. Highlight the Data Monitor tab.

The table consisting of 5 columns and 10 rows is

displayed.

3. Move the cursor to the desired cell.

4. Choose "Calcu. Result".

The subwindow is displayed.

5. Select the item you want to refer

The cursor moves to the number right next to the

item you selected.

6. Specify the number of the quoted item and

press the ENTER key.

The symbol of the selected data appears.

Summary of Contents for Micro-Imagechecker PV310

Page 1: ......

Page 9: ...1 Names and Functions of Parts Chapter 1 Chapter 1 Names and Functions of Parts ...

Page 22: ......

Page 23: ...15 Installation and Wiring Chapter 2 Chapter 2 Installation and Wiring ...

Page 35: ...27 Input and Output Interface Ports Chapter 3 Chapter 3 Input and Output Interface Ports ...

Page 76: ......

Page 107: ...99 Setting Checkers Chapter 6 6 7 Gray Edge 6 7 1 Menu Options ...

Page 114: ...106 Setting Checkers Chapter 6 6 8 Feature Extraction 6 8 1 Menu Options ...

Page 121: ...113 Setting Checkers Chapter 6 6 9 Smart Matching 6 9 1 Menu Options ...

Page 137: ...129 Setting Checkers Chapter 6 6 11 Flaw Detection 6 11 1 Menu Options ...

Page 207: ...199 TOOL Chapter 8 Chapter 8 TOOL ...

Page 224: ......

Page 225: ...217 Environment Settings Chapter 9 Chapter 9 Environment Settings ...

Page 249: ...241 Chapter 10 Parallel Communication Chapter 10 Parallel Communication ...

Page 265: ...257 Chapter 11 RS 232C Communication Chapter 11 RS 232C Communication ...

Page 298: ......

Page 299: ...291 Chapter 12 Ethernet Communication Chapter 12 Ethernet Communication ...

Page 303: ...295 Chapter 13 Using a Compact Flash Memory Card Chapter 13 Using a Compact Flash Memory Card ...

Page 323: ...315 Chapter 15 Troubleshooting Chapter 15 Troubleshooting ...

Page 328: ......

Page 329: ...321 Chapter 16 Camera Switching Unit Chapter 16 Camera Switching Unit ...

Page 333: ...325 Chapter 17 General Specifications Chapter 17 General Specifications ...

Page 340: ......

Page 341: ...333 Chapter 18 Product Numbers Chapter 18 Product Numbers ...

Page 347: ...339 Chapter 19 Dimensions Chapter 19 Dimensions ...

Page 349: ...341 Chapter 19 Dimensions Double Speed Random Camera C Mount ANM831 Unit mm ...

Page 352: ...344 Dimensions Chapter 19 ANM88281 ANM88081 ANM8804 ANM88161 ANM88251 Unit mm ...

Page 356: ......

Page 357: ...349 Chapter 20 Appendix Chapter 20 Appendix ...

Page 358: ...350 Appendix Chapter 20 20 1 Pin Assignment of Camera Double Speed Random Camera ANM831 ...

Page 359: ...351 Chapter 20 Appendix Standard Camera ANM832 ANM83203 ...

Page 363: ...355 Record of Changes Manual No Date Revision detail ARCT1F456E March 2009 First Edition ...