64

3-4 Control Sample

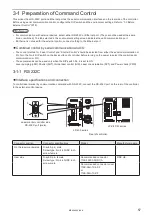

This paragraph gives the sample of flow chart for control of laser marker by serial communication.

Change setting contents

1. Laser pumping (ON)

LSR command

Remote mode OFF

2. Marking character string setting

MCS command or STR command

3. General condition setting

ALC command

4. Character condition setting

STC command

5. Laser power setting

LPW command

6. Scan speed setting

SSP command

7. Shutter (open) setting

SHT command

8. Status request

STS command

10. Command reception mode ON MKM command

11. Various conditions setting

Various command

12. Command reception mode OFF MKM command

13. Shutter setting (close)

SHT command

14. Laser pumping (OFF)

LSR command

When “10. Command reception

mode ON” is transmitted, the

commands unacceptable during

shutter open become settable

and various conditions can be set.

After setting various conditions,

set marking ready ON by “12.

Command reception mode OFF”.

The interval between “1 Laser

pumping ON” and “9 Marking

trigger” should be about 20

seconds or more with the LP-V

series, and about 15 seconds

or more with the LP-400 and

LP-W series.

Send STS command

again after a while.

“READY”: ON

Yes

To finish the marking

To change the settings

No.

Remote mode ON

9. Marking trigger

MRK command

ME-LP400V-EX-6

Summary of Contents for LP-400 Series

Page 12: ...1 Before External Control ME LP400V EX 6...

Page 24: ...2 Control by I O ME LP400V EX 6...

Page 56: ...3 Control by Serial Communication RS 232 Ethernet ME LP400V EX 6...

Page 141: ...Troubleshooting ME LP400V EX 6...

Page 158: ...Character Code Table ME LP400V EX 6...

Page 176: ...Index ME LP400V EX 6...

Page 179: ...No 9000 0062 17V...

Page 180: ...Panasonic Industrial Devices SUNX Co Ltd 2003 2018 July 2018 9000 0062 17V...