Safety

Version 1.0.1 dated 2017-11-16

Page 18

Translation of the original instructions

TX6222

GB

T

X

6222

_GB

_1.

fm

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

1.13

Safety during maintenance

Inform the operators in good time of any maintenance and repair works.

Report all safety-relevant changes and performance characteristics of the lathe. Any changes

must be documented, the operating instructions updated and machine operators instructed

accordingly.

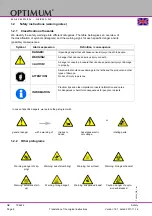

1.13.1 Disconnecting and securing the lathe

Turn off the main switch of the lathe before starting any maintenance or repair work.

Use a padlock to prevent the switch from being turned on without authorization and keep the

key in a safe place.

All machine parts as well as all dangerous voltages are switched off.

Excepted are only the positions which are marked with the adjoining pictogram. These positions

may be live, even if the main switch is switched off.

Attach a warning sign to the lathe.

WARNING!

Live parts and moves of machine parts can injure you or others dangerously!

Proceed with extreme caution if you

the lathe by turning off the main switch due to required works (e.g. functional control).

1.13.2 Using lifting equipment

WARNING!

The use of unstable lifting and load suspension equipment that might break under load

can cause severe injuries or even death.

Check to ensure that the lifting and load-suspension equipment are of sufficient load-

bearing capability and are in perfect condition.

Observe the accident prevention regulations issued by your Employers Liability

Insurance Association or other supervisory authorities applicable to your company.

Fasten the loads properly.

Never walk under suspended loads!

1.13.3 Mechanical maintenance work

Remove or install protection safety devices before starting or after completing any mainte-

nance work; this include:

covers,

safety instructions and warning signs,

grounding cables.

If you remove protection or safety devices, refit them immediately after completing the work.

Check that they are working properly!

1.14

Accident report

Inform your supervisors and Optimum Maschinen Germany GmbH immediately in the event of

accidents, possible sources of danger and any actions which almost led to an accident (near

misses).

There are many possible causes for "near misses".

The sooner they are notified, the quicker the causes can be eliminated.