64

VC_GB.fm

OPTIMUM

M

A

S

C

HI

N

E

N -

GE

R

M

A

N

Y

®

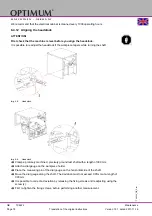

5.4

Table cutting speeds

Reference values for cutting speeds

v

c

in

m/min

when turning high speed steel and hard metal. (Excerpt from VDF 8799, Gebr. Boehringer GmbH, Göppingen)

1) The entered values apply for a chipping depth of up to 2.24 mm. From 2.24 mm to 7.1 mm the values must be reduced by 1 stage of the row R10 by approximately 20%. From 7.1 mm to 22.4

mm the values must be reduced by 1 stage of the row R5 by approximately 40%.

2) The values

v

c

must be reduced by 30 .... to 50% for turning a crust, for removal of cast skin or for sand inclusions.

3) The service life

t

for hard metal P10, K10, K20 = 240 min; for high speed steel SS = 60 min.

Material

Tensile

strength

R

m

in

N

mm

2

Cutting material

3

)

Infeed

f

in mm/rev. and setting angle

k

r

1

)

2

)

0.063

0.1

0.16

0.25

0.4

0.63

1

1.6

2.5

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

45

0

60

0

90

0

St 34; St 37; C22;

St 42

High-speed steel

50

40

34.5

45

35.5

28

35.5

28

22.4

28

22.4

18

25

20

16

20

16

12.5

16

12.5

10

up to 500

P 10

250

236

224

224

212

200

200

190

180

180

170

160

162

150

140

140

132

125

125

118

112

112

106

100

St 50; C 35

500...600

High-speed steel

45

35.5

28

35.5

28

22.4

28

22.4

18

25

20

16

20

16

12.5

16

12.5

10

12.5

10

8

P 10

224

212

200

200

180

170

160

160

150

140

140

132

125

125

118

112

112

106

100

100

95

90

St 60; C45

600...700

High-speed steel

35.5

28

22.4

28

22.4

18

25

20

16

20

16

12.5

16

12.5

10

12.5

10

8

10

8

6.3

P 10

212

200

190

190

180

170

170

160

150

150

140

132

132

125

118

118

112

106

106

100

95

St 70; C60

700...850

High-speed steel

28

22.4

18

25

20

16

12.5

16

12.5

16

12.5

10

12.5

10

8

10

8

6.3

8

6.3

5

P 10

180

170

160

160

150

140

140

132

125

125

118

112

106

100

95

95

90

85

85

80

75

Mn-;

CrNi-,

CrMo-

among others

alloyed steels

700...850

High-speed steel

25

20

16

20

16

12.5

16

12.5

10

12.5

10

8

11

9

7

9

7

5.6

7.5

6

4.5

P 10

180

170

160

160

150

140

140

132

125

125

118

112

106

100

95

95

90

85

85

80

75

850...1000

High-speed steel

20

16

12.5

16

12.5

10

12.5

10

8

10

8

6.3

8

6.3

5

7.1

5.6

4.5

5.6

4.5

3.6

P 10

140

132

125

125

118

112

100

95

90

90

85

80

71

67

63

63

60

56

56

53

50

1000..1400

High-speed steel

14

11

9

11

9

7

9

7

5.6

7

5.6

4.5

5.6

4.5

3.6

4.5

3.6

2.8

3.6

2.8

2.2

P 10

80

75

71

71

67

63

63

60

56

56

53

50

50

47.5

45

45

42.5

40

33.5

33.5

31.5

Rust-resistant steel

600..700

P 10

80

75

71

71

67

63

56

53

50

50

47.5

45

45

42.5

40

33.5

33.5

31.5

31.5

30

28

Tool steel

1500..1800

High-speed steel

9

7

5.6

5.6

4.5

3.6

4

3.2

2.5

P 10

45

42.5

40

40

37.5

35.5

35.5

33.5

31.5

28

26.5

25

25

23.4

22

22

21

20

18

17

16

Mn - High-carbon steel

P 10

33.5

33.5

31.5

31.5

30

28

28

26.5

25

22

21

20

20

19

18

18

17

16

GS-45

300..500

High-speed steel

45

35.5

28

35.5

28

22

31.5

25

20

25

20

16

20

16

12.5

16

12.5

10

12.5

10

8

P 10

150

140

132

118

112

106

106

100

95

95

90

85

85

80

75

75

71

67

67

63

60

GS-52

500..700

High-speed steel

28

22

18

25

20

16

20

16

12.5

16

12.5

10

12.5

10

8

11

9

7

9

7

5.6

P 10

106

100

95

95

90

85

85

80

75

75

71

67

67

63

60

60

56

53

53

50

47.5

GS-15

HB...2000

High-speed steel

45

40

31.5

31.5

28

22

22

20

16

18

16

12.5

12.5

11

9

11

10

8

9

8

6.3

K20

125

118

112

112

106

106

100

95

95

90

85

85

80

75

75

71

67

67

63

60

GS-25

HB

2000..2500

High-speed steel

28

25

20

20

18

14

14

12.5

10

11

10

8

9

8

6.3

7.5

6.7

5.3

6

5.3

4.25

K10

95

90

85

85

80

75

75

71

67

67

63

60

60

56

53

53

50

47.5

47.5

45

42.5

42.5

40

37.5

GTS-35

GTW-40

High-speed steel

37.5

33.5

33.5

28

26.5

25

22

21

20

18

17

16

12.5

12

11

11

10

10

9

8.5

8

K10/P10

95

90

85

85

80

75

75

71

67

67

63

60

60

56

53

53

50

47.5

47.5

45

42.5

42.5

40

37.5

White cast iron

RC420..570

K10

19

18

17

17

16

15

15

14

13.2

13.2

12.5

11.8

11.8

11.2

10.6

10.6

10

9.5

9

8.5

8

8

7.5

7.1

Cast bronze

DIN 1705

High-speed steel

53

50

47.5

47.5

45

42.5

42.5

40

37.5

37.5

35.5

33.5

31.5

30

28

28

26.5

25

25

23.6

22.4

K 20

315

300

280

280

265

250

250

236

224

224

212

200

200

190

180

180

170

160

160

150

140

140

132

125

Red brass

DIN 1705

High-speed steel

75

71

67

63

60

56

50

47.5

45

40

37.5

35.5

31.5

30

28

28

26.5

25

25

23.6

22.4

K 20

425

400

375

400

375

355

355

335

315

335

315

300

300

280

265

265

250

236

250

236

224

236

224

212

Brass

DIN 1709

HB

800..1200

High-speed steel

112

106

100

90

85

80

67

63

60

50

47.5

45

37.5

33.5

33.5

26.5

25

23.6

K 20

500

475

450

475

450

425

450

425

400

400

375

355

355

335

315

335

315

300

300

280

265

280

265

250

AL cast

DIN 1725

300..420

High-speed steel

125

118

112

100

95

85

75

71

67

56

53

50

42.5

40

37.5

31.5

30

28

25

23.6

22.4

K 20

250

236

224

224

212

200

200

190

180

180

170

160

160

150

140

140

132

125

125

118

112

118

112

106

100

95

90

Mg alloy

DIN 1729

High-speed steel

850

800

750

800

750

710

750

710

670

670

630

600

630

600

560

600

560

530

600

560

530

560

530

500

530

500

475

K 20

1600 1500 1400 1320 1250 1250 1180 1120 1120 1120 1060 1000 1000

950

900

900

850

800

800

750

710

710

670

630

630

600

560