Maintenance

Version 1.0.1 dated 2017-11-16

Page 68

Translation of the original instructions

TX6222

GB

T

X

6222

_GB

_5.

fm

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

6

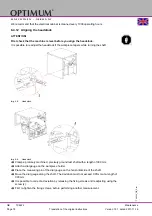

Maintenance

In this chapter you will find important information about

Inspection

Maintenance

Repair

of the lathe.

ATTENTION!

Properly performed regular maintenance is an essential prerequisite for

operational safety,

failure-free operation,

long durability of the lathe and

the quality of the products which you manufacture.

Installations and equipment from other manufacturers must also be in good order and condition.

Attention!

Never remove chips or clean the working area of the lathe with compressed air. Cleaning

inside the working area using compressed air may cause damages to the lathe.

6.1

Safety

WARNING!

The consequences of incorrect maintenance and repair work may include:

Severe injuries of persons working on the lathe,

Damage to the lathe.

Only qualified personnel should carry out maintenance and repair work on the lathe.

Validation

Check and maintain all safety-relevant stop, control and measuring devices (validation).

Documentation

Record all tests and works in a operator's log resp. log book.

6.1.1

Preparation

WARNING!

Only carry out work on the lathe, if the main switch is switched off and secured against

restarting by means of a padlock.

"Disconnecting and securing the lathe“ on page 18

Attach a warning sign.