Maintenance

Version 1.0.1 dated 2017-11-16

Page 74

Translation of the original instructions

TX6222

GB

T

X

6222

_GB

_5.

fm

OPTIMUM

M A S C H I N E N - G E R M A N Y

®

6.4

Maintenance

6.4.1

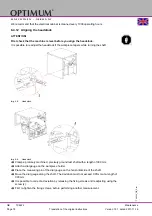

Tensioning of drive belt

The machine was delivered with preloaded drive belt. After a few hours operation, the drive belt

must be tightened again as he stretch due to being new.

The correct tension of the drive belt is subject to the experience of the maintenance staff. As a

guide, we recommend to stretch the belt, that he can push through about 25mm in the middle

between the belt pulleys with a force of 50N. The tension is correct if, upon start-up, the belt do

not slide or make noise.

Img. 6-3:

Drive belt

6.4.2

Refilling the cooling lubricant

If the cooling lubricant level is below the red mark on the sight glass, an insufficient amount of

cooling lubricant is supplied to the cutting tool. Continuing production under such conditions

results in reduced durability of the cutting tool and reduces the service life of the coolant pump.

Fill the coolant tank through the working area of the lathe.

The machine is lacquered with a one-component paint. Observe this fact when selecting your

cooling lubricant and cleaning of the machine.

A one-component lacquer with solvent part hardens when the solvent evaporates.

As soon as the lacquer is applied the solvent evaporates into the air. The binder becomes

felted and a dry film is formed. This process is reversible, i.e. the binder can be etched again

and again.

Two-component lacquer also consists of binder and solvent. However, the lacquer dries only in

connection with an added hardener. This process is not reversible, i.e. the binder cannot be

etched again and again.

The company Optimum Maschinen Germany GmbH does not assume any guarantee for sub-

sequent damages due to unsuitable cooling lubricants.

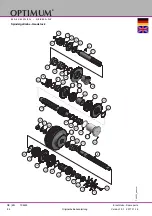

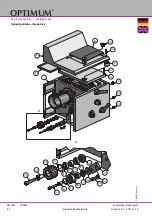

6.4.3

Replacement of the shear pin on the feed rod

A shear pin protects the feed gear at the output shaft to the feed rod. The feed gear is designed

as a sliding gear transmission. The feed rod itself is rigidly connected with the feed gear. The

overload protection of the feed gear is one via the magnetic clutch and the shear pin.

Dismantle the cover plate of the lead screw and feed rod.

Tensioning device

Motor plate

50N

25mm